Ekspert-vinnige prototiperingdienste en vervaardigers gaan dit oor vyf minute hersien

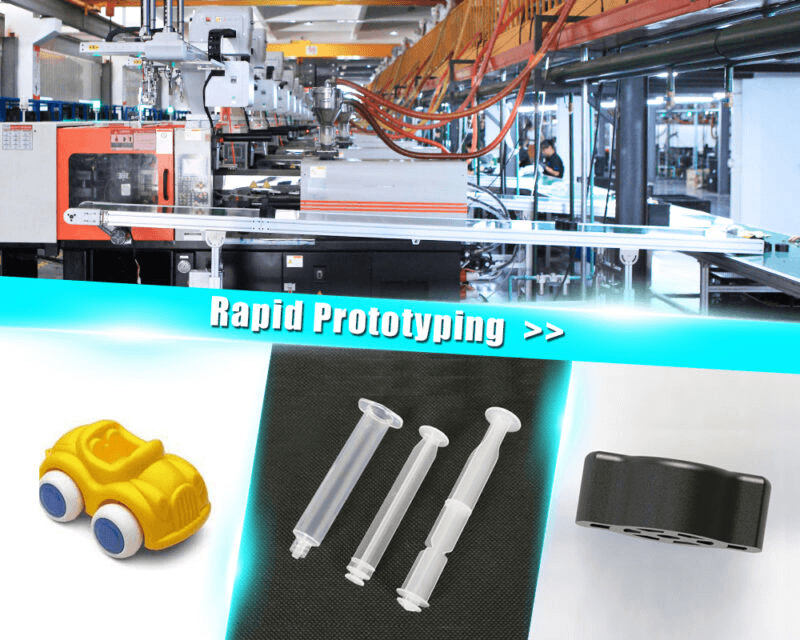

'N Inleiding tot vinnige prototiperings- en vervaardigingsondernemings

Waarom Vinnige prototipering dienste en vervaardigers

Vinnige prototipering dienste en vervaardigers wêreld verander al hoe vinniger. Dit wat jare geneem het om vandag te ontwikkel, duur maande of selfs weke. En om tred te hou met die tye, is dit noodsaaklik om aan te pas by hierdie ritmes.

Om hierdie rede is dit belangrik om die modernste tegnologieë en vaardighede van professionele persone te benut. Daarom is dit baie belangrik om die beplanning en tyd van die voltooide voorwerp aansienlik te verminder.

Die vinnige prototipering is nie net die gevolg van omgekeerde ingenieurswese nie. Maar dit is 'n wesenlike deel van die daaropvolgende ontwikkeling.

Vinnige prototipering met 3D-drukwerk

Die vinnige prototipering met 3D-drukwerk is 'n rewolusie vir die produksiemetode. Die buigsaamheid wat dit bied, bied groot geleenthede. Die proses is eenvoudig en maklik. Boonop verlaag dit die koste. Daarom is vinnige prototiperingsdienste en vervaardigers maklik te onderhou.

Vinnige prototiperingsdienste en vervaardigers met dekades se ervaring dien hierdie bedryf. Dit is 'n kosbare bondgenoot vir al die ondernemings en ontwerpers wat 'n prototipe wil maak en die doeltreffendheid daarvan wil toets.

Die grootste uitdaging vir maatskappye is vandag om die produksieproses te bespoedig. Om binne 'n kort tydjie 'n realistiese prototipe te hê, word strategies relevant. Omdat dit u in staat stel om ontwerpfoute te sien en uit te skakel.

Andersins sal dit eers na die aanvang van die produksie verskyn. Die 3D-gedrukte prototipe kan getoets en aangepas word sonder ernstige tyd- en geldmors.

Maar in werklikheid, wat is vervaardiging van vinnige prototipes in 3D?

Ons kan vinnige 3D-prototipering definieer as die stel tegnologieë. Dit maak dit moontlik om binne enkele ure 'n prototipe te bou. Dit kom uiters gemaklik en verminder ook die konstruksiekoste.

The rapid prototyping techniques vary with the rapid prototyping services and manufacturers.

Thanks to the support of 3D printers and industrial engineers can perform multiple revisions of the prototype in less time. They can perform more in-depth tests and reduce time to market.

Furthermore, the physical models are able to facilitate the communication of the concept. Similarly, they allow to obtain detailed feedback from customers and distributors.

A realistic prototype therefore becomes an extremely effective marketing tool. The possibility of obtaining a real object through rapid 3D prototyping offers the company numerous tools.

These tools improve product development, with low costs. Each department, of vinnige prototiperingsdienste en vervaardigers can have the real object in their hands. This all can be possible at the moment when the product is ready.

What can rapid prototyping services and manufacturers do for you?

3D printing is a rapidly evolving technology. To use it you need a lot of experience, as well as patience. In fact, with the current solutions available we are still far from obtaining results quickly.

Furthermore, printing errors are very difficult to avoid. Especially, if you do not have experience in choosing the design and process parameters. The printers are slow. They can take tens of hours to complete the production of a single piece of a few centimeters in size.

Rapid prototyping services and manufacturers techniques

The 3D printing has greatly increased the ability to realize. Even the most complex prototypes,

substantially giving maximum freedom to the achievable forms. On one hand the 3D printing allows to obtain a high reliability of the piece compared to the design. It provides a perfect production.

On the other hand the high speed and cost-effectiveness of the parts guarantee the

maximum customization. It gives an absolute uniqueness to each prototype made.

In both cases the huge advantage of 3D printing lies in the fidelity of the piece.

With vinnige prototiperingsdienste en vervaardigers ,you can get functional prototypes quickly. Moreover, it provides low costs starting from a simple CAD model.

Vinnige prototipering dienste en vervaardigers vir u besigheid

Deur vinnige prototipering te gebruik om finale dele te toets, kan u u produk voor die kompetisie op die mark bekendstel. Soos met 3D-drukwerk is dit makliker en vinniger om die volgende aan te bring:

- Ontwerp

- verander materiaal

- Vorms

- kleure en

- eksperimenteer met faktore

Soos die sterkte en uitvoerbaarheid van 'n produk, terwyl die koste verminder word.

Danksy die gebruik van vinnige prototiperingsdienste en vervaardigers is dit moontlik om enige tipe driedimensionele model te skep. Net so speel spesiale sagteware 'n belangrike rol in die hele proses.

Met hierdie spesiale drukkers is dit moontlik om meer as 35% op arbeid- en materiaalkoste te bespaar. Dit bespaar ook tussen 41% en 64% energie.

3D vinnige prototipering dienste in groot bedrywe

Now we hear more and more often about rapid 3D prototyping. And there are more and more companies that would like to approach this technique. They do this to improve and speed up their production processes.

To be clearer, rapid prototyping means using three-dimensional CAD modelers. We use it from desktop to convert 3D files into STL format and create prototypes in a short time.

All this therefore consists in the application of a series of industrial techniques. It allows prototypes to be created. That is nothing more than the initial elements of a production series.

Why do rapid prototyping services and manufacturers prefer 3D printing?

Met 3D-drukwerk is dit moontlik om prototipes te skep. Vinnige prototipering dienste en vervaardigers eksperimenteer op 'n eenvoudiger en beslis goedkoper manier.

3D-drukwerk is vandag die beste prototipering- en ontwerptegniek. Dit is omdat; dit maak die onafhanklike skepping van die verskillende stukke moontlik. Dit vorm 'n voorwerp. En hulle word later weer bymekaargemaak. Dit gebeur sonder om die enkele stuk te skep.

Maar wat is die beste 3D-drukkers in die omgewing?

Vinnige prototipering dienste en vervaardigers kan u van die beste modelle van 3D-drukkers bied. U kan ook 'n aantal ontwerpe kies. Maar dit hang af of u 'n kundige kies of nie.

Die beste metode is om die kwalifikasie van sodanige onderneming na te gaan. U kan vorige projekte ook vra.

Die prototipe is die eerste element van 'n toekomstige reeks. Die doel daarvan is om data te verskaf vir die evaluering van die koste. Dit handhaaf funksionaliteit en reaksies op die mark.

Vinnige prototipering is 'n stel prosesse wat die skep van 'n prototipe moontlik maak.

Die moontlike toepassingsvelde is oneindig. Dit wissel van argitektuur tot ingenieurswese. Boonop gaan dit van industriële ontwerp tot die skepping van apparate, van juweliersware tot medies.

Die materiale wat gebruik kan word, is baie en het verskillende fisiese eienskappe.

Die voordele van vervaardigingsmetodes vir Vinnige prototipering dienste en vervaardigers

- Vermindering van prototiperingskoste:

- Druk prototipes binne 'n paar uur uit

- kry terugvoer

- voltooi projekte en

- herhaal die siklus totdat die modelle perfek is

- Die koste vir die skep van clichés vir inspuitdruk word verlaag

Korter ontwerptye: druk die ontwerpsiklusse saam deur direk in 3D in die werkplek te druk.

Vinnige prototipering dienste en vervaardigers verbeter kommunikasie en verhoog interaktiwiteit. Hulle skep 'n realistiese 3D-model. Dit kan aangeraak word, dra baie meer inligting oor as 'n projek wat op papier vertoon word.

Die kritieke punte word onmiddellik waargeneem.

Verlaag ontwikkelingskoste: dit verminder prototipering- en gereedskapskoste. Dit identifiseer ook foute onmiddellik. Stelsels kan binne enkele ure prototipes oplewer.

Prototype-tye wissel volgens die:

- druktegnologieë gebruik

- die grootte en die aantal prototipes

Vinnige prototipering dienste en vervaardigers Tegnologie

Prototypes are essential in every phase of development of a new product. For this reason 3D prototype is the solution.

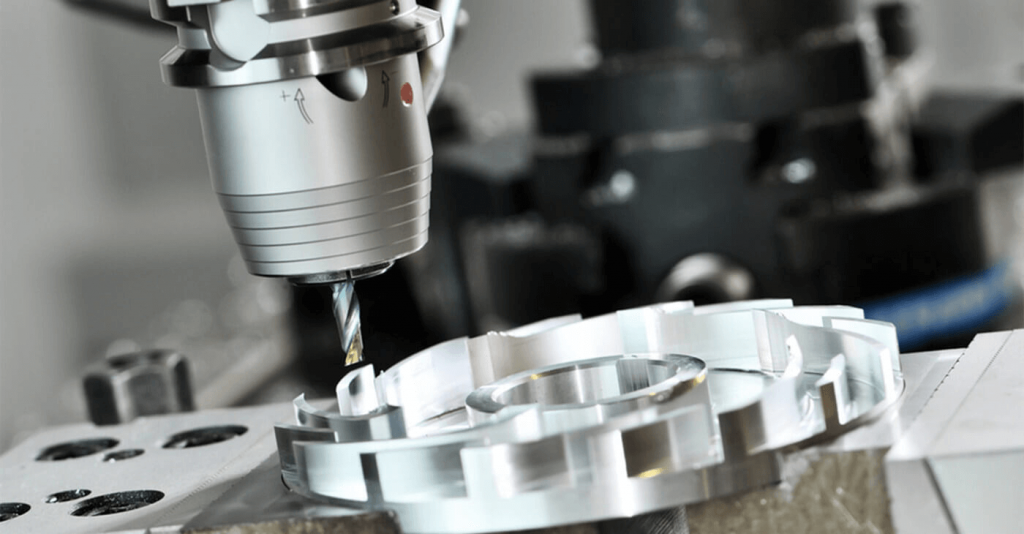

Through the laser sintering process ,it is possible to create prototypes and experiment easily. It is economical, creating components and materials suitable for visual and functional tests. Furthermore, it is one of the most precise, versatile and most used 3D printing technology.

3D printing is a rapid prototyping technique. It allows you to create prototypes and components. It provides:

- Hoë sterkte

- stability and

- precision in a short time and at low costs

Hierdie tegniek maak gebruik van termoplastiese materiale. Dit is in staat om spesifieke en meganiese eienskappe aan die gevormde voorwerp te gee. Dit is ideaal om die fases van 'n projek tydens die ontwikkeling daarvan te volg. Dit gee 'n regte tyd voor finale produksie.

Vinnige prototipering dienste en vervaardigers stel u in staat om 'n voorwerp volledig weer te gee. Dit gee u die volgende studiegebiede:

- studiemodelle te produseer

- dimensionele toetse uit te voer

- meganiese onderdele te herontwerp

- soliede reproduksies in verskillende groottes te druk

- vermindering,

- vergrotings

Hoe werk vinnige prototipe 3D-drukwerk?

Mostly, vinnige prototiperingsdienste en vervaardigers'n afsettingsdrukker. Dit laat jou toe om voorwerpe tot 70 cm hoog te druk. Dit lewer dus groot hoë-definisie-afdrukke. 'N UV-laserdrukker wat met harsfoto-reaktief werk.

Dit kan 'n baie hoë resolusie bereik . Dit gee gladde oppervlaktes en modelle. Dit is bestand teen wrywing, buiging en stryk. Net so bly hulle to the original dimensions of the CAD projects.

Ons kan die beste gebruik van hierdie tegnologie saam evalueer. Vinnige prototipering dienste en vervaardigers' professionaliteit kan die beste daarvan maak. U kan die potensiaal van 3D-drukwerk optimaal benut.

It starts from the optimization of the design up to the post-production. And, it ends with processing of the printed object.

3D printing is used as a prototyping method. It addresses 360 ° to all sectors. That needs a demonstration model for following sectors:

- from mechanicsto marketing

- design

- from industry to medical

- from jewelryto dental to teaching

'N Vinnige prototyping services and manufacturers for everyone

3D printing is one of the most debated topics in recent years. But often on the media it seems like a science-fiction technology. Similarly, it seems out of reach. But instead it is here; ready to be used in the most diverse sectors.

Let’s try to briefly explain what Vinnige prototipering dienste en vervaardigers can do to you? And what it can serve you?

Generally, 3D printing is part of a family of technologies. It goes under the classification of ‘ rapid prototyping techniques ‘. The rapid is not so much to indicate the time of realization of an object.

Since obtaining a solid by depositing very thin layers cannot necessarily be very rapid. But it indicates the advantage of not needing expensive pre-production phases. The clear example is mold making.

It also has the advantage of allowing vinnige prototiperingsdienste en vervaardigers to deposit the material. It has vast options to remove the part that is not needed. Furthermore, we can see this in milling.

Generally, it is sufficient to create a model with a 3D CAD. After a few post-production phases it is possible to ‘print’ the real and functional object.

In addition to this, the type of object creation process makes it possible to create shapes and geometries. Those are impossible with traditional methods of molding.

The impact of rapid prototyping services and manufacturers on global industries

Today vinnige prototiperingsdienste en vervaardigers are about to change production practices. It is especially for small and medium-sized companies.

There have been three pivotal events. They can testify to this passage. In 2000, a Belgian company specializing in software related to 3D printing and rapid prototyping services, collaborated with the Swiss hearing aid manufacturer.

It was Phonak to develop the first process of hearing aid-produced 3D molding devices. It demonstrated that high volume production is also sustainable via 3D printers.

In detail, 75% of the car was made by additive manufacturing. Furthermore, it used a material made of 80% ABS and 20% nylon. In short, it proved that even complex objects of large dimensions can be produced by printing them.

The third event dates back to January 2016 when a team from the University of Northwestern, Illinois developed low-cost technology. It was for printing with metallic materials.

This new process involves the use of:

- an ink composed of metallic powder

- a solvent and

- a binder

It is sprayed through a nozzle. It is common with the classic inkjet printers. Instead of resorting to the use of laser, it is sufficient to pass the model in a furnace.

Rapid prototyping services and manufacturers conclusion

Ten slotte kan ons daarop let dat 'n klein onderneming vandag verskeie instrumente en tegnologieë beskikbaar kan hê. Hulle benodig laer beleggings as die aanvang van 'n klassieke industriële produksie. En bowenal bied dit groter buigsaamheid. In die hele proses help vinnige prototiperingsdienste en vervaardigers help you a lot.

Dit is duidelik dat die groot nywerheidsgroepe hulpbronne en marksegmente het. Hulle waarborg hulle om hul leierskap te behou. Maar nisse en sektore waarin dit moontlik is om hulself as produksiemodel in te voeg.