ما هي تكلفة استئجار مصنع حقن بلاستيك في 2020؟

الفوائد الأكثر شيوعًا لتقنية صب حقن البلاستيك

مقدمة تكنولوجيا الشركة المصنعة لحقن البلاستيك

الشركة المصنعة لحقن البلاستيك مشهورة جدًا في صناعة المنتجات البلاستيكية. تستخدم كل صناعة منتجات بلاستيكية متعددة. وبالمثل ، يرتبط نطاق النشاط البشري أيضًا به. استخدام البلاستيك من مواد البناء والأجهزة المنزلية لأواني المطبخ.

The most popular method for manufacturing various products is plastic injection manufacturer technology. Moreover, modern equipment provides an opportunity to automate the production process.

And receive products with excellent technical characteristics in a short time with minimal investment. Polymer products are recyclable. Therefore, they are environmentally friendly material.

What is plastic injection manufacturer molding procedure?

Injection molding is a manufacturing process in which liquid plastic is injected under pressure into a metal mold. Evenly distributed over it and solidifies. Subsequently, this is the most common method of large-scale manufacturing of plastic products.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to الشركة المصنعة لحقن البلاستيك molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

الشركة المصنعة لحقن البلاستيك application for injecting technology

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced الشركة المصنعة لحقن البلاستيك technology:

- حاويات للمعدات الإلكترونية

- مكونات السيارات

- plastic caps and caps;

- حالات للمعدات الطبية

- قطع غيار الأجهزة المنزلية

- لعب الاطفال

- plastic packaging, etc.

فوائد الشركة المصنعة لحقن البلاستيك molding technology

Many الشركة المصنعة لحقن البلاستيك choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

Why is it recommended to choose الشركة المصنعة لحقن البلاستيك in making large batches?

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

As a result, الشركة المصنعة لحقن البلاستيك can get both simple and very complex product, with many holes and bends.

The minimum need for machining the product. More often than not, the finished product does not require any processing. Moreover, exceptions are very complex products. However, in this case, the improvements are minimal.

منتجات نهائية غير محدودة.

The metal mold, which is created before production, will last a very long time. Subsequently, with its help you can make any number of products.

تكلفة منخفضة تخضع لتصنيع دفعة كبيرة.

The more products will be manufactured, the cheaper the cost of one copy. Because the main budget is spent at the stage of preparatory work. Hence, it is carried out only once.

في الوقت نفسه ، فإن الشركة المصنعة لحقن البلاستيك لها عيوبها.

- ارتفاع تكلفة الأعمال التحضيرية ، و

- وفقًا لذلك ، عدم جدوى تصنيع منتج ما في نسخة واحدة أو دفعة صغيرة.

المراحل الرئيسية لإنتاج المنتج بالحقن

تتضمن عملية تصنيع المنتجات البلاستيكية عن طريق القولبة بالحقن عدة مراحل. بشكل عام يمكن تقسيمها إلى مجموعتين:

- العمل التحضيري و

- يلقي نفسه.

دعونا نفكر في هذه المراحل بمزيد من التفصيل.

العمل التحضيري

إنشاء نماذج ثلاثية الأبعاد للمنتج المستقبلي. يمكنك إنشاء نموذج ثلاثي الأبعاد وفقًا للرسومات أو الوصف أو الصورة. يتم تنفيذ النمذجة ثلاثية الأبعاد في برنامج خاص بواسطة متخصص متمرس.

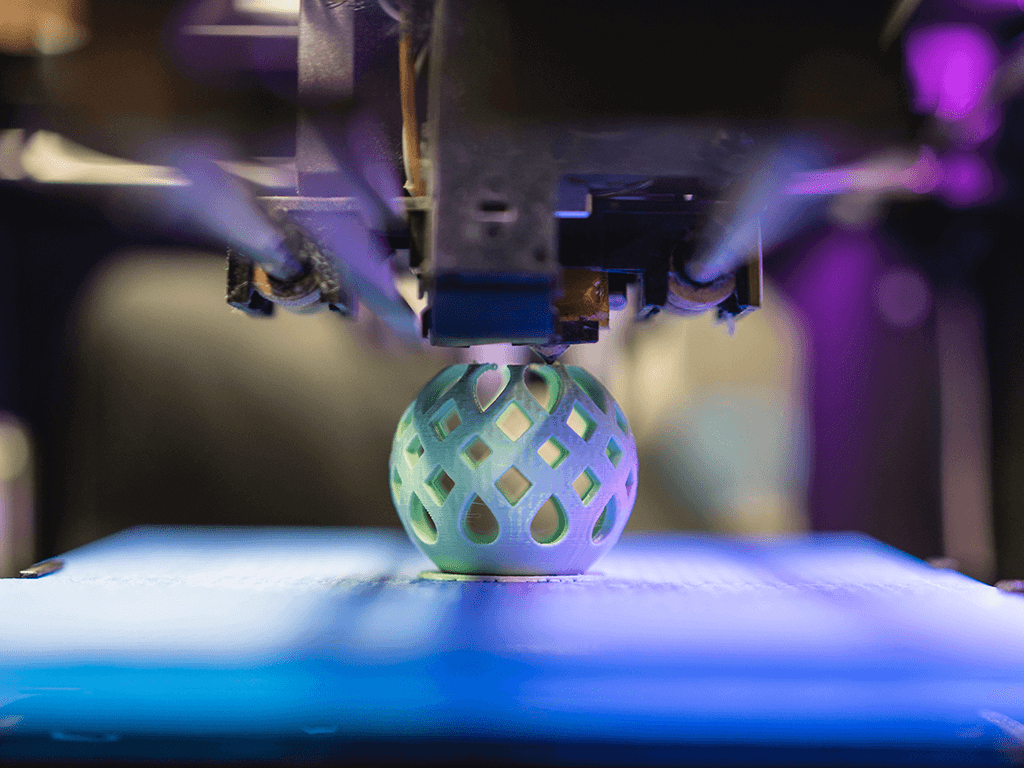

تصنيع النموذج الأولي.

بعد إنشاء النموذج ثلاثي الأبعاد والموافقة عليه ، يمكنك إنشاء نموذج أولي ، أي عينة من المنتج المستقبلي. يتم ذلك غالبًا باستخدام الطباعة ثلاثية الأبعاد.

النموذج الأولي ضروري لتقييم واختبار المنتج المستقبلي.

إذا تم العثور على أي أخطاء ، فمن الضروري العودة إلى المرحلة الأولى والانتهاء من النموذج الثلاثي الأبعاد.

تصميم قوالب.

تعتمد هذه العملية على نموذج ثلاثي الأبعاد للمنتج المستقبلي. عند التصميم ، من المهم مصنعي حقن البلاستيك مراعاة جميع التفاصيل الدقيقة.

صنع القالب.

ينقسم النموذج ثلاثي الأبعاد النهائي إلى عدة أجزاء. علاوة على ذلك ، كل جزء مصنوع على حدة. وبعد ذلك يتم تجميعها في قالب.

اختبار الصب.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which الشركة المصنعة لحقن البلاستيك should not rush. Because the quality of future products depends on it.

Injection molding process of plastic injection manufacturer

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

- type of plastic

- mold temperature, etc.

- For small items, this is usually a few seconds.

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

What is the cost of plastic injection manufacturer for producing injection mo0lding product?

As a rule, the الشركة المصنعة لحقن البلاستيك by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

- The complexity of theThe higher it is, the more expensive the mold will be, and accordingly, each product.

- Type of plastic. The material is selected based on the requirements for the final product.

- Number ofpieces in a batch. The more of them, the cheaper each product, and other significant factors.

The advantages of plastic injection manufacturer technology

For the production of large batches of polymer products, الشركة المصنعة لحقن البلاستيك technology of plastics is characterized by the advantages of high precision casting. By injecting the molten mass at an increased rate, uniform filling of the mold is ensured, including microscopic holes. Generally, the method is characterized by many advantages, due to which it is popular:

- Possibility of manufacturing products of any geometric shape and degree of complexity.

- Thin-walled parts are made. The complexity of the design depends on the mold.

- Moreover, it has high detail and takes into account all the bends. As well as the holes of the future product.

- No need for plastic injection manufacturer for subsequent machining of parts.

- Similarly, some complex products may undergo minimal processing.

- Mass production of unlimited plastic parts. The life of metal molds is tens of years.

- So, they are used to manufacture a huge number of polymer products.

- Quick payback when organizing the production of a large batch of plastic products. At the same time, the cost of one product is reduced.

- without quality deterioration with an increase in the number of copies produced.

plastic injection manufacturer equipment features

الحياة الحديثة غير ممكنة بدون الشركة المصنعة لحقن البلاستيك البلاستيك. وهم في أي مجال وفي أي مجال. و الشركة المصنعة لحقن البلاستيك المعدات يجب أن تفي بجميع متطلبات العملاء. مهتم بإنتاج منتجات بلاستيكية عالية الجودة ومتينة. تلخيصًا ، يجب تخصيص المعدات وفقًا لاحتياجات العملاء.

إذا كان بإمكاننا مساعدتك في مشروعك ، فيرجى الاتصال بنا على 0086-769-82821468 أو إرسال بريد إلكتروني إلى sales@kaitomould.com.