The Prototyping and Rapid Prototyping Services, We Offer

Prototyping and Rapid Prototyping Services

Modern businesses are able to test the viability of their idea with the help of rapid prototyping services. Instead of going it mass production and then finding the errors, it now possible to eliminate all errors before you enter the manufacturing phase.

The powerful innovation “Rapid Prototyping” allows the manufacturer to reduce the product to the market time. Instead of months, you can yield the same result within days. What more is that specialized prototype service providers are able to decrease the lead time that is required to manufacture a viable prototype.

The Fundamentals

Rapid prototyping is a concept that uses a number of independent strategies that work together in order to reduce the time required for fabricating three-dimensional, full-scale shapes. The process starts with the computer-aided design files, the hardware uses these specifications to automate the fabrication process.

It eliminates the need for manual labor that is needed for the creation of figures and mock-ups. In order to do so, manufacturers may use a number of techniques including machinery, computer numerical control, CNC or 3D printing.

Why Is it Important?

In the 1980s, the development in the technology led to the faster and more promising prototyping. It could efficiently create real-world objects from digital designs. Before this progress, the manufacturers were to rely on artists for the creation of mock-ups.

For instance, in the case of automobile mock-ups, the sculptors used clays to create partial-scale replicas.

The rapid popularity of the prototyping method reflected several pertinent factors. For example, turning computers into industrial tools was a major step forward. The decision was gaining steam for the industry.

These techniques and systems rapidly become prominent and acceptable throughout the industry. Also, the companies no longer had to spend time on hiring software engineers, or time-share serves. They were able to accomplish a lot more in less time and a limited budget.

Computers allowed them to play around with the different fabrication processes throughout the product’s life cycle.

Since the prototyping stage is the first stage in product development, therefore applying this technology to it was the wise thing to do. The increase in competition in the manufacturing industry was another reason that people readily accepted this technology.

It offered them the facility to play around with ideas without worrying about the failure cost. Countries like the USA were always interested in the realm of machine tooling. Also, they predicted the future, as well as more and more companies with globalized backgrounds, were entering the market.

The only way to survive was the innovation of technology. Designing and developing unique products and launching them before the competitors.

Services, We Offer

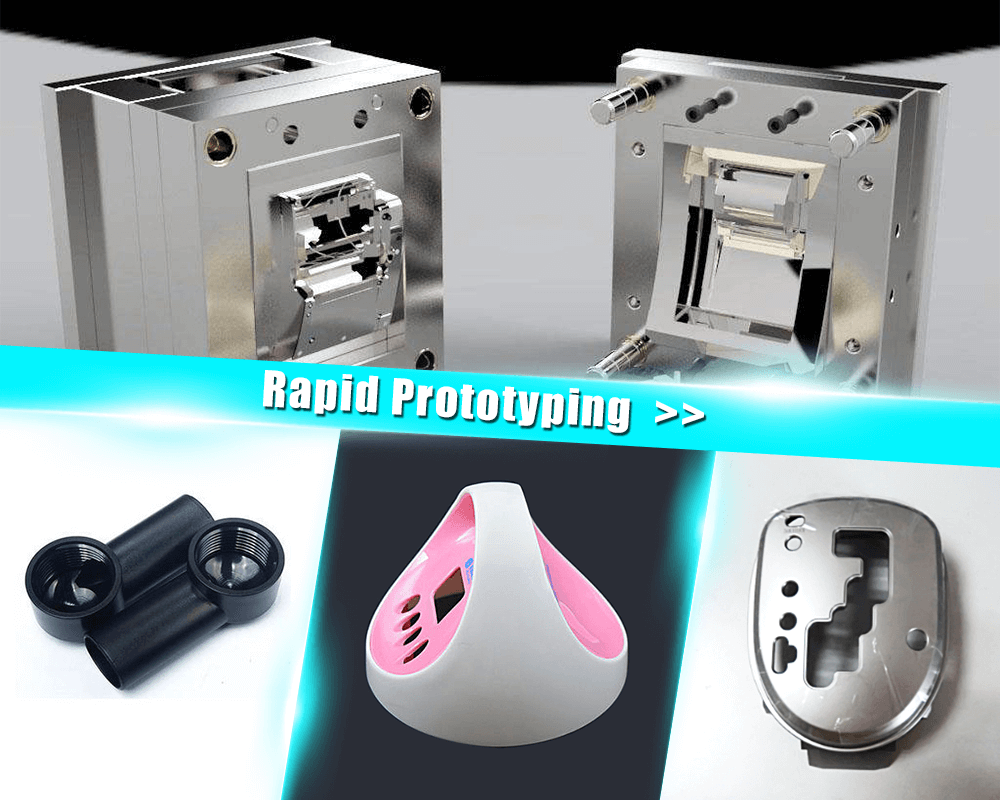

In order to compete in the challenging business world today, we have highly skilled prototyping experts and mechanical engineers. These engineers can design and develop high precision models as quickly as possible. They can work within the flexible timelines.

At, Katio Mould, we can provide you high-quality prototyping and rapid prototyping services cost-efficiently and effectively. Below, are some of the customized services that we offer.

Selective Laser Sintering

SLS tools are necessary for modern prototyping services. Our team is highly skilled in developing prototyping models using Selective Laser Sintering tools. They can create a high-quality, powerful, and accurate prototype structure by combining the sinter powdered material and the laser power source.

Stereolithography

Our team is well-equipped in all sort of technology required to create sophisticated, yet solid prototypes. Katio Mould can create realistic prototypes using different SLA tools. Our team is able to fully emulate the product’s functional feature because due to the layer-by-layer process.

Polyjet 3D Printing

To produce on-demand prototypes, we use precision 3D printing. Our developers and designers ensure that they incorporate the lasted 3D printing techniques and technologies to ensure the quality and accuracy of the prototype parts.

3D-CAD Modeling

We have years of experience in creating rapid prototypes using the CAD simulation environment. Therefore, our team has full command when it comes to drafting and CAD modeling.

Our Rapid-Prototyping Process Flow

To ensure the smooth development of prototypes, our designers and developers follow the process below.

Requirement Analysis

The first step towards the development of prototyping is allocating resources, finalizing scope, and decide on a time-line.

Creation of Prototype

In this step, our highly skilled team uses the requirement and creates a CAD model. They then convert the model to the STL format file. Using this file, they would turn the digital design into a real-world object. Lastly, they would do all the required final touches.

Quality Check

At this stage, Katio Mould specialist would perform all the required functional testing and they will acquire the client’s consent.

Final Delivery

Our team would make all the required modifications before they deliver the prototype to the consumer.

Why Should You Outsource Rapid Prototyping Services To the US?

When you are assessing when and how to outsource your rapid prototyping services, keep the seven benefits that we offer in mind.

Since we firmly believe in quality, therefore, we maintain the highest quality control standards throughout the prototyping process. It is our aim to satisfy your expectations for quality and accuracy.

We offer outstanding prototypes services at extremely reasonable rates. Thus, allowing new project budgets as well as enhancing the bottom line.

We have the best onboard, therefore, we ensure that every project that we undertake would be delivered on time and within budget.

With our short turnaround times, our clients are able to check the reliability of their concept. They are able to test their ideas using our customized prototyping services.

Our round the clock customer care service would answer all your questions regarding prototyping services.

We can design and develop fully functional prototypes, reducing the unanticipated risk of developing a new product.

You would not need to hire new employees in order to analyze the advanced prototypes. On the contrary, our skilled and experience prototyping team would do that for you.

Outsource your Prototyping Services to Us

We being the leaders in the prototyping and rapid prototyping would ensure high-quality, accurate, and fully-function prototypes. Our services are not limited to the ones mentioned above. For more information, you can contact us today. We will provide you with complete prototyping services.