Wichtige Design-Tipps Hersteller von Kunststoffspritzteilen

Top 10 Design-Tipps für Hersteller von Kunststoffspritzteilen

Als Hersteller von Kunststoffspritzteilen müssten Sie sich in erster Linie auf die Konstruktion von Teilen und Komponenten konzentrieren. Schließlich spielt das Design eine entscheidende Rolle für den Erfolg der Teile. Das richtige Design mit der richtigen Ausführung würde die richtigen Ergebnisse erzielen.

A wrong design with the right execution is bound to be a disaster. Therefore, manufacturers around the globe tend to pay close heed to the design factor. They need to understand the consumer’s requirements, analyze their capacity and then finalize a design.

Your design majorly depends on the consumer’s requirement. However, certain factors would ensure the right design. In the course of this article, we are going to talk about the top 10 designing tips.

Top Ten Designing Tips

Injection-molded components offer several benefits including scalability, uniformity, mass production and much more. With injection molding, you can effortlessly design complex parts and produce them in volume without any problem.

To ensure repeatability, you need to follow the designing tips below.

Constant Wall Thickness

When it comes to uniformity, there is no better way to achieve it than to ensure constant wall thickness of the mold cavity. This would ensure that the component provides the best flow. A good size of the wall is around 2-3mm.

For conventional molding, we generally recommend that you use maximum 4mm and minimum 1mm of wall thickness

Draft Angle – plastic injection parts manufacturer

You might be surprised to know the advantages a draft angle has to offer. adding a draft angle to your part’s faces ensures that the tools quickly release it. However, do bear in mind that draft angels do cause design challenges.

Manufacturers that are in for mating parts would have a serious problem with the draft angle. So, to make the best out of draft angle for textured cavity surfaces use a minimum of 3 degrees. In the case of the untextured core, we recommend at least 1 degree of draft angles.

Smooth Trumps Sharp

Another important tip is to avoid a sharp transition between walls sections at all costs. When there isn’t any sharp transition, it would lead to problems in the final product. In addition, it is a good idea to use radii wherever you think it is possible.

Zero Draft Surface

Eine gute Technik besteht darin, keine Zugluftflächen zu vermeiden. Verwenden Sie sie nur, wenn sie notwendig sind. Wenn Sie Toleranzen und eine ordnungsgemäße Teileverbindung sicherstellen können, ohne den Null-Zug-Bereich zu verwenden, sollten Sie ihn nicht verwenden. Stellen Sie außerdem sicher, dass Sie die Verwendung auf einen bestimmten Bereich des Gesichts anstatt auf die gesamte Oberfläche beschränken.

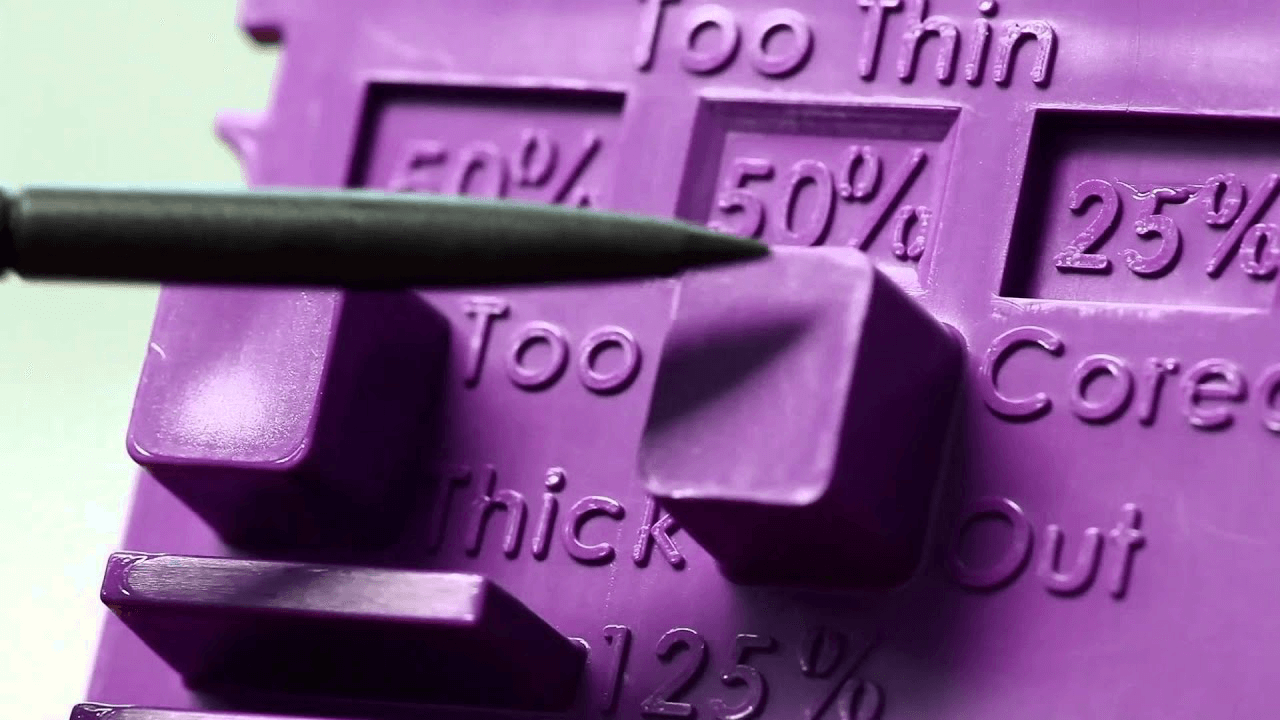

Dick bis dünn Übergang

Um die Qualität der Teile sicherzustellen, sollten Sie sicherstellen, dass Kunststoff über Merkmale fließt, die sich von dickeren zu dickeren Wänden bewegen. Das alles sollte also direkt vor den Toren beginnen.

Hersteller von Waschbecken - Kunststoffspritzteilen

Wenn ein dickerer Abschnitt der Teile im Vergleich zum dünneren Abschnitt dazu neigt, langsam abzukühlen, führt dies zu einer lokalen Vertiefung. Mit dem richtigen Design können Sie dieses spezielle Problem vermeiden. Mit den richtigen Richtlinien können Sie die Sichtbarkeit von Fehlern auf kosmetischen Oberflächen beseitigen.

Im Folgenden haben wir einige wichtige Hinweise aufgeführt.

- Vermeiden Sie Schraubnaben, Rippen und Tore auf der Rückseite kosmetischer Oberflächen. Dies wird ihre Lebensdauer verlängern.

- Stellen Sie sicher, dass die Rippenhöhe geringer als die Wandstärke ist. Sie können es sogar 3x machen.

- Die Basis der Rippen sollte entweder 60% oder weniger der Wandstärke betragen.

Einfachheit

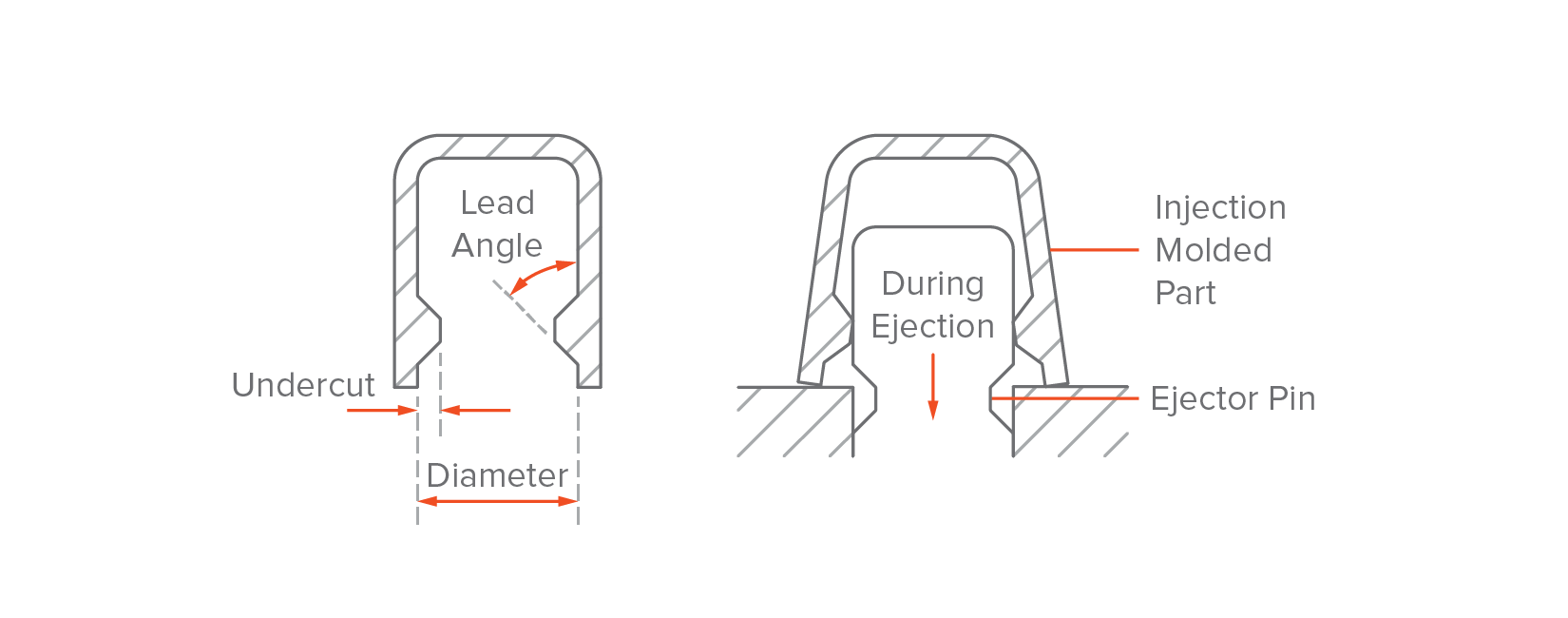

Manchmal ist Einfachheit der Schlüssel zu hochwertigen und robusten Teilen. Als Hersteller von Kunststoffspritzteilensollten Sie Hinterschneidungen vermeiden. Wenn Sie mehr als nur möchten, lassen Sie Folien und Lifter Features zu, die unterboten sind.

In diesem Fall müssen Sie etwa die zwei- bis dreifache Breite des Features belassen. Dies würde es dem Schlitten oder dem Lifter ermöglichen, sich reibungslos zu bewegen.

Hinweis: Hinterschneidungen sind die Rückstände, die Hersteller mit den einfachen Anweisungen zum Öffnen und Schließen des Werkzeugs nicht erzielen können.

Use Datums

Using datums enhances the readability and understanding of the design. In case, you are wondering what are datums? They are the reference points that define every part. With datums, you can establish part interaction and interface to the entire system.

Using the right datum system would ensure the success of the product in terms of functionality. In addition, you should make sure that design’s intent of assembly is in correspondent to the datum structure.

Prototype

Plastic injection manufacturers often use custom 3D printing services for reliable and efficient parts. After all, prototyping methods cut down design to market time. With prototyping, it is possible to test the design concepts at an early stage.

Thus, the manufacturer can mold a part or its respective component before getting down to building expensive tools.

Design for Manufacturing Reports

Never, and we repeat, never underestimate the Design for Manufacturing reports. You should never take these reports lightly. With these reports, you can learn about the tool molder’s understanding of the design.

It will provide you information like the ejector pin locations, parting line location, gate location among others. DFM reports allow you to efficiently, interrogate the design.

Advance Designing Tips

Here, we have listed the advance designing tips.

Tool-bound Features

Features you create by the same piece of mold tend to have a tighter relative position tolerance. Examples of these features include slide, core, cavity, etc. Similarly, features that are created using different mold parts have less position tolerance.

Molded-In Texture

It is possible to mold the visible surfaces via innate textures. Among the major advantages of textured parts, we have hiding sinks, fingerprints, etc. Although, t molded-in texture offers great benefits, at the same time they require a more draft angle.

Ultrasonic Welding

The modern technique allows pressing 2 compatible parts into contact. It also ensures that these parts are supported in a tooled fixture. The key to remember here is that you have to design the parts for ultrasonic welding.

Also, ensure that the parts have a singular welding plan. In addition, one of the parts needs to have teh energy directors. These directors will help with the welding. To form contacts, the part without the energy directors would be excited using ultrasonic vibrations.

These vibrations would help to locally, fuse the part with the other part. With the help of these ultrasonic welding, it is possible to create weatherproof bonded assemblies and that too at a low cost. However, plastic injection parts manufacturer needs to know that some resins bound better in comparison to others.

Pass Cores

Pass cores are an effective way to create a hole in your part. They are basically parts of the molds. One side of the mold passes via part’s piece, and the opposite side is shut off. This makes it possible for the manufacturer to make overhangs.

Experienced designers can play around with pass cores to come up with unique and amazing parts. They can create complex features including shaft’s bores.

Family Molds

When you shoot two or more parts in the same mold, you name the process as family molds. Family molds are effective and affordable especially when you are molding a small number of parts having similar volume and using the same material.

However, you need to ensure that all the parts fill properly. For this reason, you would have to perform a good mold-flow analysis.

Select Resin via molder

Ever resin has its unique characteristics. Their additives for changing things like UL fire rating, UV exposure, colors, impact properties, etc. would need some special attention. We recommend that you trust the molder with this decision.

Give them a list of characteristics of very resin, along with your requirements and let them help you choose the best resin for your parts.

Final Word – plastic injection parts manufacturer

Designing is imperative for any successful Hersteller von Kunststoffspritzteilen. With the right design, they would be able to develop accurate, robust and reliable products. Therefore, it a good idea to follow these tips to ensure the accuracy and quality of the design.

Wenn wir Ihnen bei Ihrem Projekt helfen können, rufen Sie uns bitte unter 0086-769-82821468 an oder senden .