¿Cuánto cuesta contratar un fabricante de inyección de plástico en 2020?

Beneficios más populares de la tecnología de moldeo por inyección de plástico

Introducción a la tecnología del fabricante de inyección de plástico

fabricante de inyección de plástico es bastante famoso en la industria de productos plásticos. Cada industria usa múltiples productos plásticos. Del mismo modo, el ámbito de la actividad humana también está asociado a él. El uso de plástico desde materiales de construcción y electrodomésticos hasta utensilios de cocina.

The most popular method for manufacturing various products is plastic injection manufacturer technology. Moreover, modern equipment provides an opportunity to automate the production process.

And receive products with excellent technical characteristics in a short time with minimal investment. Polymer products are recyclable. Therefore, they are environmentally friendly material.

What is plastic injection manufacturer molding procedure?

Injection molding is a manufacturing process in which liquid plastic is injected under pressure into a metal mold. Evenly distributed over it and solidifies. Subsequently, this is the most common method of large-scale manufacturing of plastic products.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to fabricante de inyección de plástico molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

fabricante de inyección de plástico application for injecting technology

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced fabricante de inyección de plástico technology :

- enclosures for electronic equipment;

- automotive components;

- plastic caps and caps;

- cases for medical equipment;

- household appliance parts;

- Kids toys;

- plastic packaging, etc.

Benefits of fabricante de inyección de plástico molding technology

Many fabricante de inyección de plástico choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

Why is it recommended to choose fabricante de inyección de plástico in making large batches?

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

Como resultado, fabricante de inyección de plástico puede obtener un producto simple y muy complejo, con muchos agujeros y dobleces.

La mínima necesidad de mecanizado del producto. La mayoría de las veces, el producto terminado no requiere ningún procesamiento. Además, las excepciones son productos muy complejos. Sin embargo, en este caso, las mejoras son mínimas.

Productos terminados ilimitados.

El molde de metal, que se crea antes de la producción, durará mucho tiempo. Posteriormente, con su ayuda podrás realizar cualquier cantidad de productos.

Bajo costo sujeto a la fabricación de un gran lote.

Cuantos más productos se fabriquen, más barato será el costo de una copia. Porque el presupuesto principal se gasta en la etapa de trabajo preparatorio. Por tanto, se realiza una sola vez.

Al mismo tiempo, fabricante de inyección de plástico tiene sus inconvenientes.

- el alto costo del trabajo preparatorio, y

- en consecuencia, la falta de rentabilidad de fabricar un producto en una sola copia o en un pequeño lote.

LAS PRINCIPALES ETAPAS DE LA FABRICACIÓN DEL PRODUCTO MEDIANTE MOLDEO POR INYECCIÓN

El proceso de fabricación de productos plásticos mediante moldeo por inyección consta de varias etapas. Generalmente, se puede dividir en dos grupos:

- trabajo preparatorio y

- casting a sí mismo.

Consideremos estas etapas con más detalle.

Trabajo de preparatoria

Creación de modelos 3D del futuro producto. Puede crear un modelo 3D de acuerdo con los dibujos, la descripción o la fotografía. El modelado tridimensional se lleva a cabo en un programa especial por un especialista experimentado.

Fabricación de prototipos.

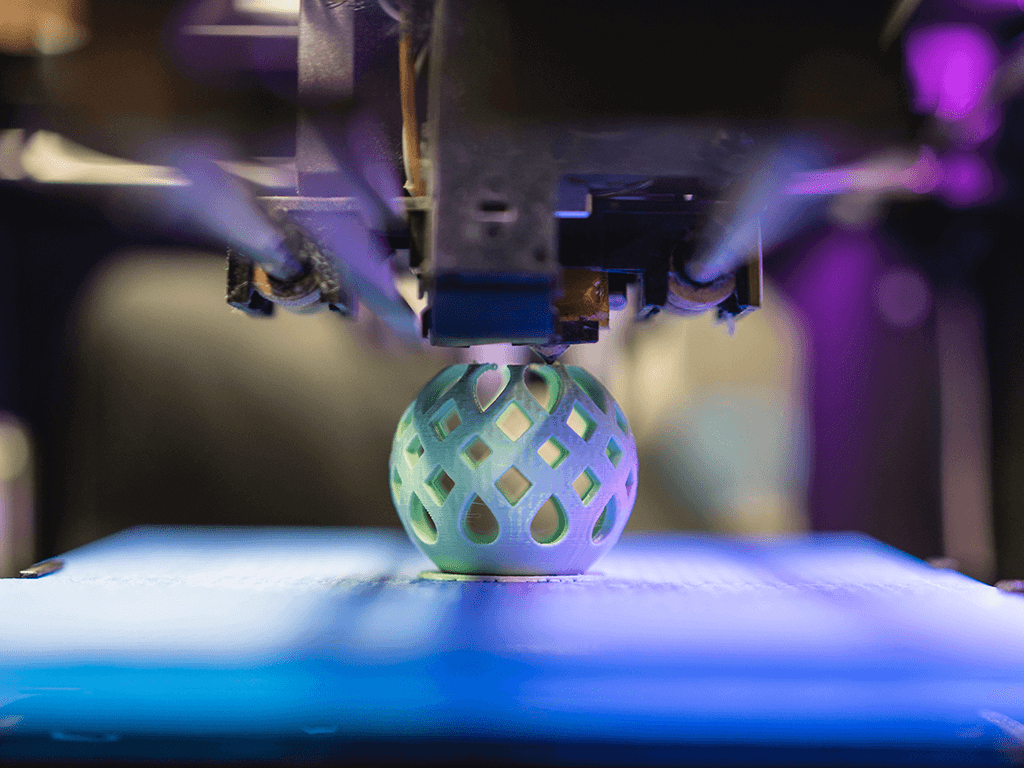

After the 3D model is created and approved, you can create a prototype, i.e. sample of the future product. This is most often done using 3D printing.

A prototype is necessary in order to evaluate and test the future product.

If any inaccuracies were found, it is necessary to return to the first stage and finalize the 3D model.

Mold design.

This process is based on a 3D model of the future product. When designing, it is important for the fabricantes de inyección de plástico to consider all the smallest details and subtleties.

Mold making.

The finished 3D model is divided into several parts. Moreover, each part is made separately. After which they are assembled into a mold.

Test casting.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which fabricante de inyección de plástico should not rush. Because the quality of future products depends on it.

Injection molding process of plastic injection manufacturer

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

- type of plastic

- mold temperature, etc.

- For small items, this is usually a few seconds.

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

What is the cost of plastic injection manufacturer for producing injection mo0lding product?

As a rule, the fabricante de inyección de plástico by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

- The complexity of theThe higher it is, the more expensive the mold will be, and accordingly, each product.

- Type of plastic. The material is selected based on the requirements for the final product.

- Number ofpieces in a batch. The more of them, the cheaper each product, and other significant factors.

The advantages of plastic injection manufacturer technology

For the production of large batches of polymer products, fabricante de inyección de plástico technology of plastics is characterized by the advantages of high precision casting. By injecting the molten mass at an increased rate, uniform filling of the mold is ensured, including microscopic holes. Generally, the method is characterized by many advantages, due to which it is popular:

- Possibility of manufacturing products of any geometric shape and degree of complexity.

- Thin-walled parts are made. The complexity of the design depends on the mold.

- Moreover, it has high detail and takes into account all the bends. As well as the holes of the future product.

- No need for plastic injection manufacturer for subsequent machining of parts.

- Similarly, some complex products may undergo minimal processing.

- Mass production of unlimited plastic parts. The life of metal molds is tens of years.

- So, they are used to manufacture a huge number of polymer products.

- Quick payback when organizing the production of a large batch of plastic products. At the same time, the cost of one product is reduced.

- without quality deterioration with an increase in the number of copies produced.

plastic injection manufacturer equipment features

La vida moderna no es posible sin fabricante de inyección de plástico plástico del fabricante de inyección de plástico debe cumplir con todos los requisitos de un cliente. Interesado en la producción de productos plásticos duraderos y de alta calidad. En resumen, el equipo debe personalizarse según las necesidades del cliente.

Si podemos ayudarlo con su proyecto, llámenos al 0086-769-82821468 o envíe un .