¿Por qué los fabricantes de moldes de plástico personalizados enfatizan el proceso de fabricación de moldes?

¿Cómo fabrican moldes los fabricantes de moldes de plástico personalizados?

Cuando se trata de fabricar sus piezas personalizadas, lo más importante es el molde. Si tiene un molde sin errores, puede tener piezas y componentes sin errores. Por lo tanto, debe comprender los conceptos básicos de cómo los fabricantes de moldes de plástico personalizados hacen moldes.

Si su objetivo es producir piezas personalizadas de gran volumen, debe considerar el molde de inyección . Existen diferentes tipos de moldeo por inyección . Elija el que mejor se adapte a sus necesidades de perfección.

Sin embargo, antes de comenzar cualquier proyecto, es importante considerar factores como el tamaño de las piezas, la fabricación de estas piezas, el presupuesto de herramientas, el material utilizado o la cantidad de piezas. Además, sería genial aprender sobre las máquinas básicas para fabricar moldes.

Entonces, en esta publicación de blog, cubriremos todos estos aspectos. Entonces, sin más demora, ¡comencemos!

Molde de plástico personalizado - Fabricación de moldes

Determinación de la cantidad de piezas

If you are aiming for high volume custom plastic products, you should be planning for at least 100,000 parts or more. This is usually the minimum quantity required by most custom plastic mold manufacturers.

Therefore, it is important to consider your product plans and whether you need that kind of part or components number.

Creating and Evaluating your Tooling Budget

Another important factor that requires consideration is your budget for tooling. This includes your design and creation of the tool. Make sure you look into every aspect before you go ahead with your project.

The complexity of your mold will directly influence its cost. So, a good idea is to reduce mold complexity. Try to make it as simple as possible to keep the cost low. Also, focus on other aspects that would help you reduce the cost.

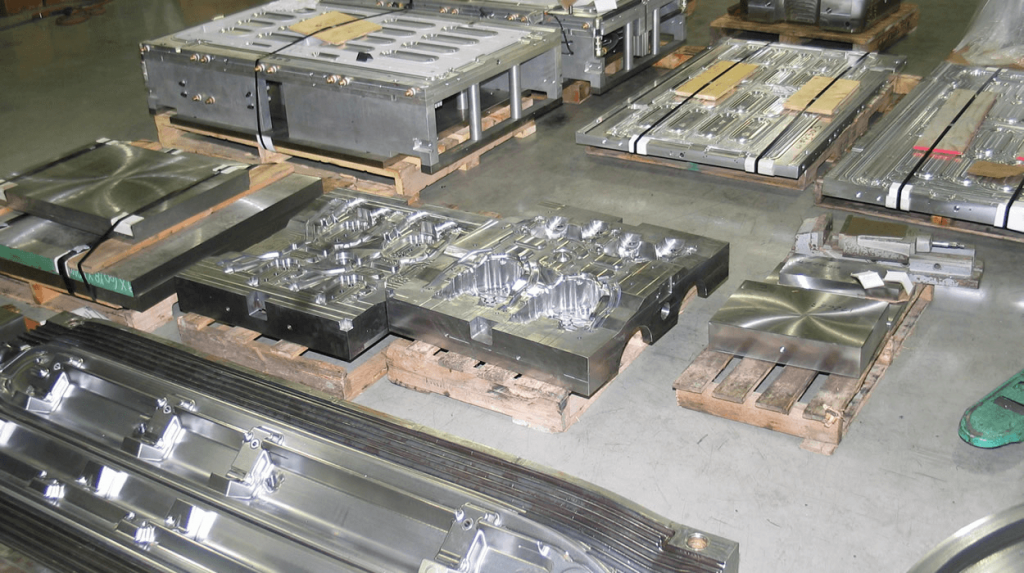

Also, focus on the tools that you would use for the creation of molds. Below, we have listed some common and popular tools.

Standard CNC Machining

The orthodox form of the CNC machining requires milling, manual use of lathes, and drill presses. However, with technological advancement, the CNC machining has become the most dominant means of creating complex and high-level molds.

While it is using the standard machining methods, it still can produce complex molds. With CNC, they use computers to control the operation and movement of the lathers, mills, and other several cutting machines.

However, modern CNC machining systems have become sophisticated and advance. The current systems are fully automated in terms of mold designing and manufacturing processes.

It now uses a computer-aided manufacturing software (CAM) to define the mechanical dimensions of the mold. The instructions are translated into specific commands using a post-processor software. This is imperative for every machine that creates a mold.

The resulting command is loaded into the CNC machine for the manufacturing process to start.

Electrical Discharge Machining

Another famous machine for making molds is electrical discharge machining (EDM). This process uses an electrode to obtain the desired shape of the mold. The shape is fabricated out of copper or graphite. Next, comes the mounting in the EDM machine.

Later, it is positioned over the workpiece. It is submerged in a dielectric fluid. The workpiece comes into contact with the electrode. Thus, you would be using a controlled electrical source to disperse the metal in different areas that are opposite to the electrode.

The workpiece never comes in contact with the electrode. There is always a gap between the electrode and the workpiece. The gap is a few thousandths of an inch. Although, the EDM process is slower when it comes to removing the metal from the mold especially when you compare it with the CNC machining.

However, with EDM the fabricantes de moldes de plástico personalizados are able to acquire the most difficult shapes. Something they are not able to achieve via the conventional CNC machining. Another great thing about the EDM process is that it provides the facility of working with pre-hardened molds.

Thus, it eliminates the requirement of additional heat-treating methods. What more is that the finial resulting of EDM finishes tends to be the final finish. You do not recover additional working on the polishing of the mold cavity.

Mold Design

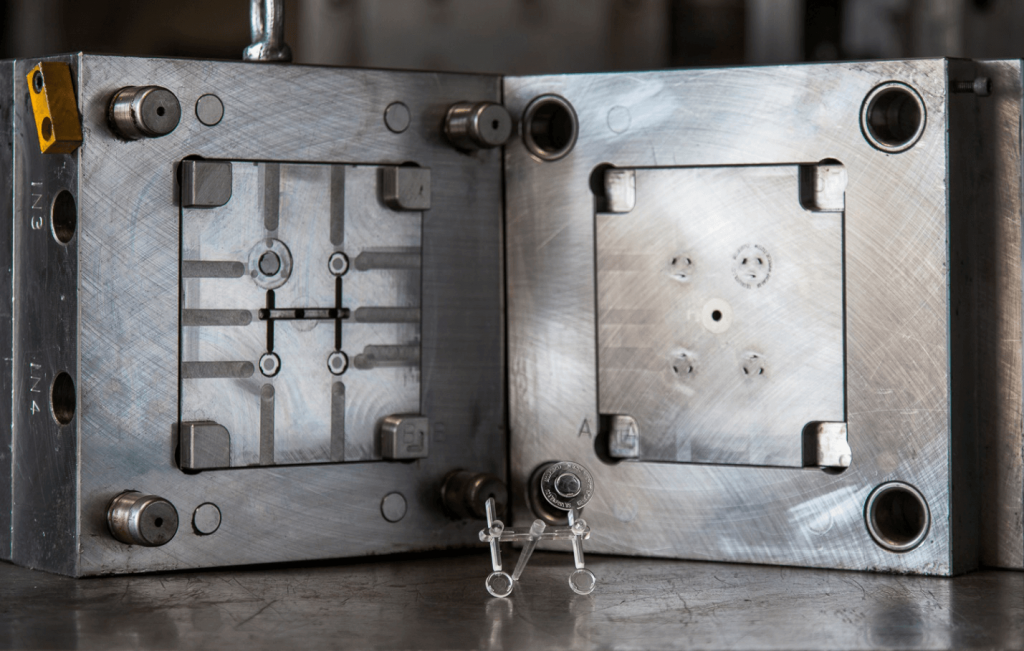

There are two main components of the plastic injection molds, first is the cavity half of the mold and the second is the ejector half of the mold. It is important for the mold halves to work in conjunction. Below, is how they work together.

The plastic resin from the molding machine would enter through the gate or the sprue on the first half of the mould.

Injection barrel’s nozzles have a sprue tightly sealed against it. This ensures that the molten plastic tends to flow seamlessly from the barrel to the cavity or the mold.

The molten plastic is passed through different channels – runners. The sprue bushing is responsible for the direction of the channels. These channels have access to the faces of both the first and the second half of the mold.

The molten plastic enters a specialized gate via the runners. Thus, allowing the molten plastic to enter the cavity in order to shape the requested parts.

While designing the mold, it is important to remember that the molded parts reliably remain in the second half of the mold when it opens.

Los fabricantes extraen el bebedero y los canales de la primera mitad del molde. Así, permitiendo que la pieza moldeada caiga libremente una vez, se expulsa de la segunda mitad al molde.

Un solo molde de inyección de plástico tiene una sola cavidad. Esto significa que tiene la capacidad de producir solo una parte a la vez. Es posible que los moldes tengan múltiples cavidades. Asegurando moldes de alta producción. Por ejemplo, los moldes de una tapa de botella pueden tener más de 100 cavidades. Por lo tanto, puede producir múltiples tapas de botellas al mismo tiempo.

Consideraciones de tamaño y producción de diseño

No es posible crear todas las piezas mediante el proceso de moldeo por inyección. Los buenos fabricantes de moldes de plástico personalizados evaluarían el diseño antes de aprobarlo. Trabajarían en el diseño, realizarían cambios si fuera necesario para garantizar que se produzca una pieza estructuralmente sólida.

Además, la optimización del diseño ayudaría a reducir el costo. Los diseñadores realizarían todos los cambios necesarios para garantizar que las partes funcionen y sean precisas. Si necesita piezas de menor tamaño, le recomendamos que utilice el proceso de moldeo por inyección.

En este caso, asegúrese de que el diseño no sea mayor de 10 x 10 x 10 pulgadas. Por lo tanto, debe considerar diferentes formas en las que su diseño puede aprovechar partes más pequeñas en mayor número. En comparación con las piezas más grandes pero con menos piezas.

Los fabricantes de moldes de plástico personalizados se centran en el material

Es imperativo centrarse en el material que utilizaría para sus productos y piezas. Hay ciertos diseños que permiten flexibilidad, mientras que algunos requieren requisitos específicos debido a un material en particular.

Rely on your manufacturer’s advice when it comes to choosing the right material. After all, they have the experience as to how a certain material would work with their injection moulding process. They would also be able to offer you an equally good substitute for an expensive material.

After all, they have been in the industry long enough to understand all its ups and downs. They would be the most authentic source of information for you.

Para llevar

permítanos is among the leading custom plastic mold manufacturers. They have been providing high quality and effective injection moulding services for several years now. Their experience and their knowledge of the industry would help them deliver high-quality parts or components.

They will help you with creating your part design. Furthermore, they would evaluate it for the use in production as well as producing your mold.

You should reach out to them today, discuss your design, and allow them to translate your ideas into reality. After all, we are the leading injection molding company.