Fabricant de pièces moulées en plastique: différence entre le thermoformage et l'extrusion

Fabricant de pièces moulées en plastique: Moulage par extrusion Vs Thermoformage

Un fabricant de pièces moulées en plastique offre une diversité de techniques de moulage. En plus des méthodes de moulage populaires telles que l' injection et la rotation. Il existe deux techniques de moulage plus efficaces, à savoir le thermoformage et le moulage par extrusion.

Both of these techniques offer a number of benefits. They come with their advantages and disadvantages. Although, both techniques offer to end up moulding plastic, but the way they go about it is different. In this article, we are going to talk about the difference between these two techniques.

What a Plastic Molded Parts Manufacturer has to say about these techniques?

Having a basic understanding of both these techniques would help you make a better decision when it comes to choosing a plastic moulding method for your custom plastic parts.

Extrusion Molding

The process of extrusion molding is similar to that of injection molding. However, there is a slight difference, it tends to produce a long continuous shape. In addition, extrusion molding does not use a mold, on the contrary, it uses a die.

To make the parts, the technique squeezes hot raw material via a custom die. To make it easier for you to understand, we can say that it is like squeezing play Doh via a shaped hole. Unlike other molding techniques that put resins into a mould, extrusion puts it directly into the die shape.

So, here the die instead of the mold determines the shape of the desired product.

The Step by Step Process

Step 1: Raw plastic material including powder, pellets, granules are put into a hopper, later the material is shifted into an extruder. It is a hot long cylindrical chamber. To move the material through the chamber, it uses a revolving screw.

There are some extruders more than one revolving screw.

Step 2: There is a spinning screw operating, the raw material flows from the hoppers onto this spinning screw. For the operation of the spinning screw, it uses a horizontal barrel.

Step 3: Since every material has different properties, therefore the heating for every raw material is different. The temperature requirement of a certain material is taken into account. To form the desired shape, the molten plastic is passed through the die.

It is the small opening present at the end of the heated chamber.

Step 4: For the cooling purposes, the plastic extruded from the die is placed onto a conveyor belt. A plastic molded parts manufacturer can use either air or water for the cooling down purpose.

The process is similar to that of the injection molding. However, instead of the mould, here you would be using a die.

Step 5: It is important to design the die for every individual plastic profile. This would ensure the smooth flow of plastic from the cylindrical profile to the extruder. Thus, taking the final shape.

To ensure that the end product offers integrity, consistency in the flow is imperative.

Extrusion Moulding Common Use

If you want the parts to have a cross-sectional profile, use the extrusion moulding technique. For instance, PVC piping, hoses, and the straws. There is no need for the parts to be round. However, it is vital for them to have the same shape along the part’s length.

When you compare the cost of extrusion molding to other moulding process, you will realize that it is cost-efficient. Mainly because of the die and the machine are simple. They lack the complexity that is innate in molds and machines of other moulding processes.

Since it lacks complexity, thus it has its limitation. You can create only a number of products via this particular technique.

Best Uses of Extrusion Molding

You can design and manufacture parts that are simple and have a fixed cross-sectional profile. For instance, products are either have a circle shape and square.

Common Products

- Plastic Gutters

- PVC pipe

- Plastic Decking

- Straws and Hoses

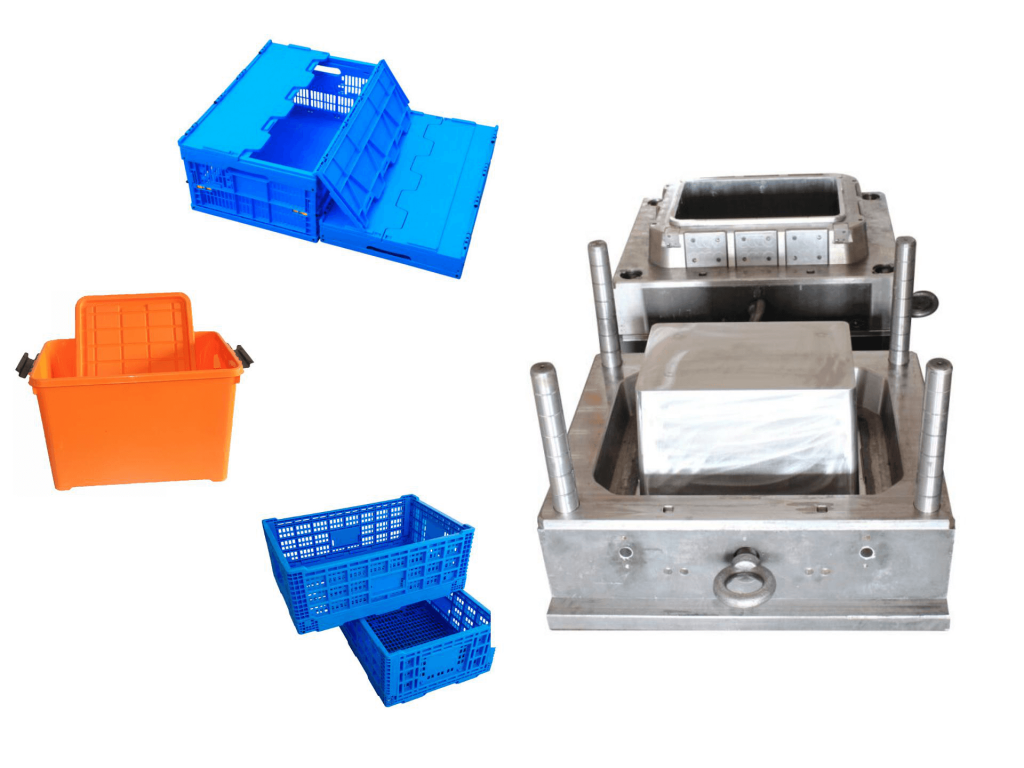

Thermoforming

Thermoforming is an effective manufacturing process in which the sheet plastic – thermoplastic—is heated to forming temperature. The reason for doing so is to allow the sheet to form the specific shape in the mould.

It later is trimmed to create products. The great thing about thermoplastic sheets is that it comes in a wide range of materials, thickness, finishes, and colors.

To achieve the final product thermoforming does not reply to a certain type of process or a mould. On the contrary, it uses multiple molds along with the different processes to acquire the required shape. For 3D products, it is generally a single 3D mould.

Plastic Mould Parts Manufacturer uses aluminum for the creation of these 3D molds. Since the technique uses less pressure, therefore, it is possible to create parts or components at a lower rate.

Types of Thermoforming

There are two basic types of thermoforming: pressure forming and vacuum forming. Both techniques yield effective results, but there is a slight difference between the two.

Vacuum forming uses pressure and heat to draw the plastic into the respective shape. It first heats the sheet and then places it into the mould. To ensure that the plastic takes the final shape, it is manipulated using the vacuum.

La formation sous pression, en revanche, est similaire à un vide. Cependant, il a l'avantage supplémentaire de la pression. Avec la pression, il est possible d'obtenir plus de détails et de texture. Par conséquent, si vous devez choisir, entre les deux, la formation sous pression est le meilleur choix.

Utilisations courantes de thermoformage

Le thermoformage, en particulier la jauge d'étain, est extrêmement populaire pour la production de barquettes, blisters, récipients, gobelets jetables, coquilles, couvercles entre autres. C'est courant dans le secteur de l'alimentation comme dans le secteur de la vente au détail en général.

Pour quelque chose de plus robuste et plus gros, les fabricants optent pour le thermoformage épais. Par exemple, il s'agit d'une technique efficace pour les doublures de réfrigérateur, les portes de véhicules, les lits de véhicules utilitaires et les panneaux de tableau de bord.

Coût et temps de production

The thermoforming may be an inexpensive plastic moulding technique; however, it does take time. On average, you would need around 8 weeks for the thermoform mold to be ready. After the mold is ready, production starts.

The manufacturing phase is faster. However, do bear in mind that the cost of the technique greatly depends upon the size of the part of the component. For instance, if you want to mold small size parts, it would cost you $20,000 a year.

Whereas, the same amount of parts with a bigger size would cost you $50,000 a year.

You can also check out our article on how to reduce cost per unit.

Plastic Molded Parts Manufacturer Offering the following benefits

Here are the benefits of both Thermoforming as well as the Extrusion molding technique.

Extrusion Molding Advantages

High speed, High Volume

Le processus est rentable lorsque vous souhaitez fabriquer un grand nombre de pièces ou de composants. Il peut également produire des pièces rapidement.

À bas prix

Lorsque vous comparez le moulage par extrusion à un certain nombre d'autres techniques de moulage telles que la rotation, vous le trouverez abordable. De plus, cela permet à l'installation de réutiliser les restes de matériaux, réduisant non seulement le résultat des déchets, mais aussi le coût.

La machinerie est robuste, elle peut fonctionner en continu. Les fabricants peuvent profiter d'une période de fabrication de 24 heures par jour.

Souplesse

Les produits ont une section transversale cohérente; cependant, il offre une flexibilité considérable. Vous pouvez profiter d'un certain nombre de formes, de tailles et de textures avec le processus de moulage par extrusion.

Avantages du thermoformage

Adaptabilité

Le thermoformage offre de nombreux avantages, l'adaptabilité de la conception étant au top. La technique offre la flexibilité d'intégrer tous les besoins de conception des consommateurs.

Délai d'exécution rapide

Bien sûr, pour une production complète, le moule prend un certain temps. Cependant, dans le cas du prototype, il peut fournir des résultats efficaces en un rien de temps. Il offre un temps de rotation rapide.

Optimisation des matériaux

Avec le thermoformage, il est possible d'optimiser les matériaux afin de garantir des coûts d'outillage inférieurs ainsi qu'une fabrication rentable.

De plus, la technique offre un certain nombre d'autres avantages. Il en résulte un composant ou une pièce très esthétique. Le fabricant de pièces moulées en plastique propose des plastiques pouvant être peints, des plastiques colorés, ainsi que plusieurs autres options de personnalisation.