Importance of 5 M’s for Injection Molding Manufacturers

The 5 M’s of Injection Molding Manufacturers – Part I

For smart injection molding manufacturers, the 5 Ms (Man, Material, Machines, Method & Metrics) carry great value. We understand many of you might not be familiar with these Ms. You might be thinking, how are they related to the molding industry. What do they refer to?

We will be addressing all your questions shortly. We will provide you complete detail on every M. However, it is not possible to explain everything in just a single article. Therefore, we will be addressing the first 2 M’s in this article and the remaining in other articles.

Introduction to 5 M’s

5 M’s basically address the 5 important components of the industry, namely man, material machine, methods and metrics. They are used to improve the efficiency of the enterprise. The company uses software, hardware, services and technology to come up with all-inclusive and effective solutions.

When manufacturers end up developing a faulty product, they spend a lot of time, money and energy in order to identify the cause. Sometimes, they end up making significant changes without having any solid reason to do so. Most technicians believe that their idea would work. However, smart organizations do make major changes so effortlessly.

On the contrary, they would first consider the 5 M’s and then make the required changes. They do understand that there is more than one-factor affecting productivity. These detractors could be big or small, they could be sporadic or consistent. Sometimes they are obvious, others are hidden.

It is imperative for an improvement-minded facility to conduct a periodical analysis of t every aspect of the designing, production and developing performance. After all the failure and success of every company firmly depend upon the timely identification of system failures and inconsistencies.

Once they are able to identify the problem via effective reviewing, the next step is to take precautionary measures and implement improvements. They need to come up with approaches that are more refined. In some cases, they might have to grade their technology, better train their employees and equip them with sophisticated equipment.

Key Requirements

We have already established the fact that more numerous factors affect the productivity of a company. However, to ensure profitable continuous improvement, the companies need to focus on some key requirements.

One of these key requirements is having a solid base to start with. The injection moulding manufacturers need to understand that every aspect of a certain line needs to be in order. For instance, when they turn the product from design to production, ensure that the design line is stable.

A lack in the designing phase is bound to create an issue in the production phase, and thereafter. Ensuring every line is in order would prevent costly downtime. In addition, it will make sure that a faulty product does not reach the consumer.

A company can ensure the smooth working of every aspect by paying close heed to the 5 key components. The injection molding suppliers should constantly review these components for continuous improvement.

We are going to outline these principles and recommend ways in which you can incorporate them for better performance of your companies.

Man (Labor): The First M

There is no denying the importance of labor to the success and failure of any company. Despite technological advancement, there are several areas in plastic operations where labor plays a critical role.

They can have both positive as well as negative effects on product development. Labor tends to have an impact on the consistency and repeatability of the operations.

Below, we came up with some important points that will help you evaluate your labor in a better way.

Work Area

Effective injection molding manufacturers want to deliver top-notch quality products to their consumers. Therefore, they evaluate every step they take.

They understand that engineering does end with taking the parts out of mould. On the contrary, it incorporates the entire process and workplace where the product is developed.

Pay attention to the working environment. Ensure that it has the right amount of light. Marking of location is also important, so mark scrap bin, tools, tables, etc. A good way to maximize operator efficiency is to have a well-designed area.

Make sure to eliminate the waste of motion. Smooth passing of inspection, packaging and part preparation is imperative. This will allow the operator to a comfortable environment and ample time to conduct a thorough search.

Note: When the job becomes more labor-intensive, it has a direct impact on the quality of the product. This adverse effect is the result of human error. Thus, a decrease in the quality of the end product.

Tools

Once the workspace is as per the required standards, the injection moulding manufacturers then need to focus on the tools. In order to do that the manufacturers should pay heed to the workers. After all, they are the people who are most involved in the production end.

They are the ones are who working on the product day in, day out. They would have a better picture of how things are going and what would be the result. To ensure comfortability and increase productivity, pay heed to their suggestions and concerns.

They will find the area of improvement. In addition, make sure to equip them with the tools that they need in order to accomplish what you need. The right tools will ensure efficiency and effectiveness.

Work Place Injuries

Many manufacturers often overlook this category. However, what they fail to understand is that frequent workplace injury leads to increased insurance costs. This overhead is inevitable and it eventually leads to reduced profitability of almost every project.

When developing the work instruction, carefully look for the troublesome areas. Focus on the job areas that require turning, bending and twisting. Evaluate the methods and come up with effective solutions that will help increase workflow on the floor.

Defects

An important thing to understand here is that every aspect of the product starting from engineering till production should meet the highest standards. After all, the objective is to mold in the quality instead of sorting for it.

Manufacturers might come across situation where they have to depend upon the operators. Therefore, it is necessary to have experienced and well-trained operators.

Brief them properly so that they exactly know what defect they are searching for. Also, guide them towards the areas that in general are troublesome.

A good idea to identify common defects is to track scrap. Once you find the defect, look for the solution. See if the problem can be resolved by modifying molds, changing material or making changes in the process. These steps will reduce the risk of defects significantly.

Human Error

There is always a possibility that things might not work out as you have planned. There is always room for error. Instead of complaining, review the error. This will help you come up with solutions that eliminate failures from happening again.

There are different methods to get to the root cause of a failure or defect. Our favorite is the “5 Why” method.

Instructions

After the establishment of the work pattern, work instructions are of great importance. The operational instruction is a tool that has a direct impact on productivity. Therefore, injection molding manufacturers need to take great care in providing directions to every personnel.

Make sure to give concise and clear directions on their job requirement. Add charts, pictures in your guideline to enhance readability and understanding. The objective is to write simple and easily understandable work instructions.

The Mold: The Second M

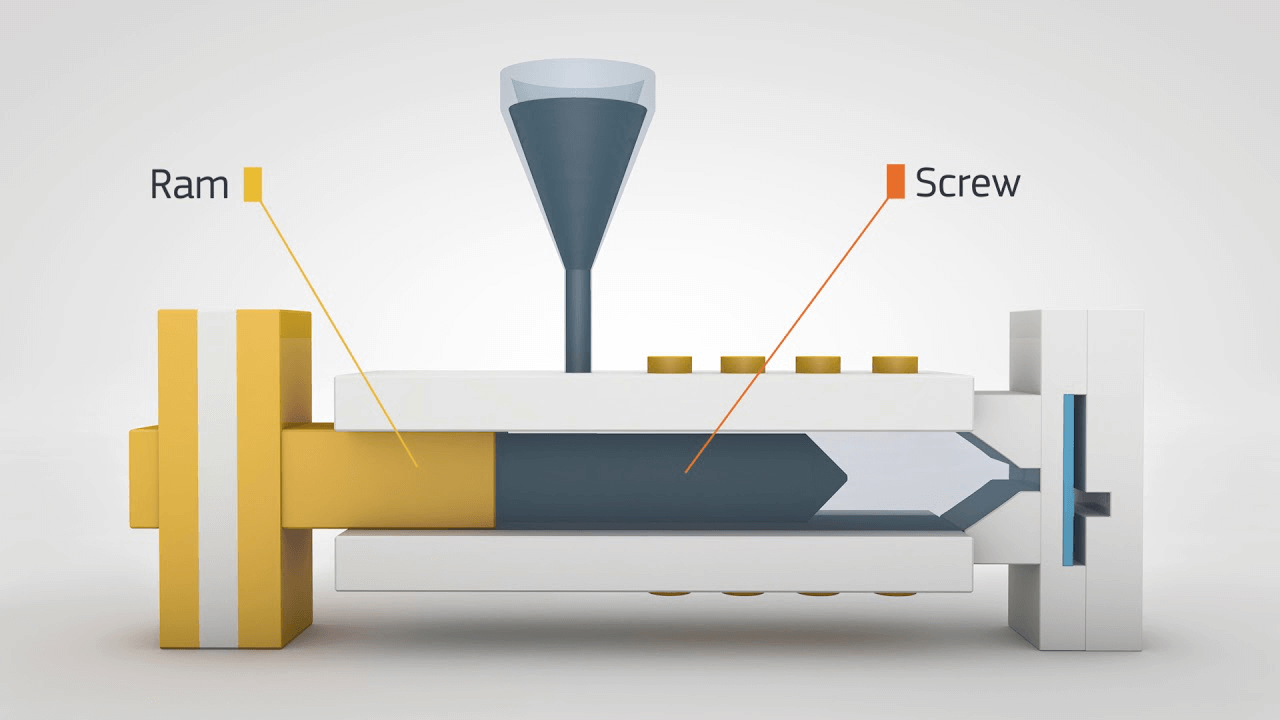

To develop a product to perfection, you need to have all the right tools intact. After all, tooling is the key foundation block. Thus, the injection molding suppliers need to ensure that they have the perfect mold.

A low quality, improperly functioning and poorly designed mold can lead to systematic failure. Any product you create using that particular mold will turn out to be a failure. Therefore, you need to review your molds along with other continuous improvement projects.

Regular reviewing of your mold for potential improvements would enhance the quality of the final product. Below, we have focused on some of the important areas that you should consider as tools that need regular evaluation and review.

Design

Designing is the most important part of the mold. The manufacturer should ensure that the design is according to the requirement of a particular application. They need to concentrate on both the design specification and the quality of the molds.

Molds that have frequent breakage or poor processing capabilities do not perform well. They are crippling the manufacturer’s efficiency and productivity.

You should analyze the mold pressure fluctuation, performance of the flowfront and mold temperature would allow designers to make adjustments in order to overcome current or potential problems.

Qualification Tooling

Mold qualification has several aspects. However, the main objective of qualifying a mold is to come up with a tool that has the ability to produce consistent quality parts over a certain time. Below, we listed areas that are important to mold qualification.

Runner System

In order to control his process, the molder needs to verify either cavitation is balanced or not. It is important that all parts have the same weight and consistency. In case there are parts with different weights, molders need to adjust the gates. Gates, runners, and Srpue would allow balanced filling according to the properties of the materials.

Mold Temperature

If the heating and cooling of the mold have consistency, it would lead to consistency in the processes. Check multiple areas of the mold faces to make sure that every part of the mold as the same and consistent temperature.

In case the temperature varies, it would lead to inconsistency in the parts. Thus, eventually leading to systematic failure. You might have to either add or remove the circuits to accomplish consistency. Another important factor is to mark mold circuitry.

Clear marking of the circuitry would help prevent irregular setups. It would also offer consistent directions and right turbulent flow. So measure the variability of the mold temperature, you need to test it in a running state. This would ensure if the mold has a consistent temperature.

In addition, the manufacturer would be able to identify if the hot or colds spots in the mold are affecting the process during molding.

Venting

It is important to ensure that molds come with adequate venting to meet the needs of the respective molding application.

Validation Process

Process validation establishes that a process is dependable and true. The inspection molding manufacturers will be able to rely on the consistently of the process. In addition, they could effortlessly repeat it.

Below are the primary process controls that require reviewing. These controls would assure process validation.

Barrel Temperature

The injection molding manufacturers need to compare set points with actual temperature in a running state. Conditions that increase the temperature more than the set points always lead towards process inconsistency.

Melt Temperature

The melt temperature needs to within the recommended limits of the MSDS data. The material manufacturer is responsible for providing this data.

Peak Pressure

Injection moulding manufacturers need to verify that the pressure at cut-off is consistent. In general, the pressure setpoint is around 200 PSI higher than the achieved peak pressure.

Cushion

To guarantee the stability of the process, cushion consistency is critical.

Fill Time vs. Velocity

The fill time of the process determines the injection speed. Therefore, it is vital for the speed to be adjustable. The process variance increases and the injection speeds max out due to the lack of decrease in the fill time, despite the increase in velocity.

Mold and Area

Numerous situations have an impact on the process’s repeatability. See these factors below.

Water

A consistent repeat of the water set up is critical. Clear identification of return lines and the supply helps with the prevention of a change in the circulation from one set to another.

Clamp Force

Injection molding manufacturers need to ensure that the tonnage setpoints are consistent as lack of consistency would lead to poor flash and venting.

Hot runner

Try using the same hot runner box with the same mold to yield consistency.

If we can help you with your project please call us at 0086-769-82821468 or email sales@kaitomould.com.