Prototipo rapido di parti CNC 2020: questo è ciò che fanno i professionisti con parti cnc personalizzate?

Le parti lavorate a CNC sono così semplici da capire

Un'introduzione al prototipo rapido di parti CNC

Oggi l'uso di Prototipo rapido di parti CNC è diventato incredibilmente importante per le moderne tecnologie. E le parti CNC e la prototipazione rapida sono infatti la forma innovativa di prototipazione. Oggi le aziende di successo stanno facendo uso di metodologie nuove e avanzate per lo sviluppo dei loro prodotti.

And its big example is prototyping. Nowadays use of rapid prototyping has become part and parcel in manufacturing the following:

- the final designs of products

- in procedures and materials

- in complex technologies.

Nowadays innovation has totally changed in this advanced distribution. And it is also very important to know that under what terms businesses and brands operate.

In the preparation of your brands, it is very important to ensure all of your regular customers that your products are truelly developed using digital innovation.

So, for you it is really important to use all digital innovation in your designed productslike rapid prototyping. Furthermore, CNC partsrapid prototype is also making progress in order to fasten the innovation.

Che cos'è il prototipi rapidi di parti CNC?

Rapid prototype is basically the procedure of confirming all the potentials which actually a product has. A prototype looks like the final design as users can easily understand all its functions.

Furthermore, it also makes the users able to give feedback about all its basic characteristics. Moreover it helps in following ways like:

- it saves time

- it also saves money

But when user gives positive feedback, manufacturers confirm this prototipi rapidi di parti CNCas the final design of the product. In this way engineers admit that prototype is on point which they actually need. So, rapid prototyping also assists in making the progressive development of the products.

Ma i produttori fondamentalmente usano la parola rapida per spiegare la velocità reale. Inoltre, il prototipo rapido dipende dal feedback che riceve. Più velocemente gli utenti danno il feedback, più il produttore corregge i suoi difetti.

Quindi, i produttori devono mantenere l'equilibrio tra la fabbricazione di prototipi rapidi di parti CNC davvero tutte le caratteristiche. In modo che gli utenti abbiano la capacità di fornire feedback effettivi e corretti per correggere il prototipo rapido come ultimo progetto.

Quante tecnologie utilizzano i produttori per creare prototipi rapidi di parti CNC?

Esistono fondamentalmente due tecnologie principali che i produttori utilizzano per creare prototipi rapidi.

Questi sono:

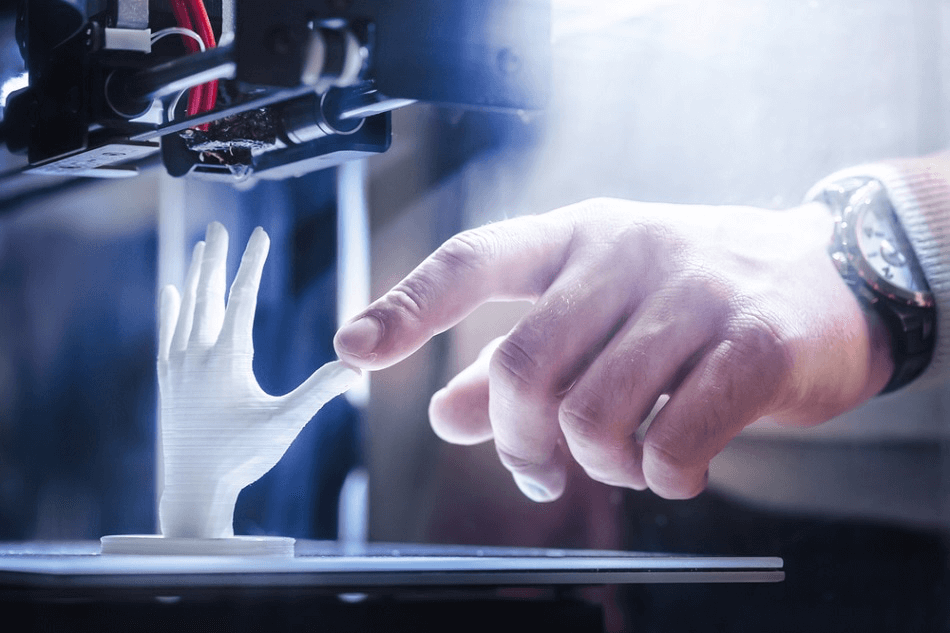

- Stampa 3D

- Lavorazione CNC.

And both of these technologies have benefits to create prototypes rapidly. They also have the ability to remove all repetitions of final designs. But there are many kinds of businesses that use both of these technologies.

So, it is essential for the manufacturers to understand basic dissimilarities between the both.

What are the main differences between 3D printing and CNC machining to create CNCparts rapid prototype?

If you have basic knowledge about all the major technologies which engineers use in creatingPrototipo rapido di parti CNC. Then certainly you will understand that basically there are various differences between CNC machining and 3D printing.

Here are some details about the both CNC machining and 3D printing. And these are:

CNC machining:

CNC machining is generally famous as a reductive form of manufacturing.

It means that it can produce 3D models at a huge solid piece of some special material through machining or working away.

3D printing:

On the other hand, 3D printing is basically famous as an additive form of manufacturing. Moreover, it also has ability to involve CAD. It powers the printer in order to create a product in several layers.

However, these differences are quite basic and crucial. Furthermore, it depends on the needs of engineers that which technology is best for their purposes. Specially when, they have need to make use of Prototipo rapido di parti CNC.

Which technology is best for creating prototipi rapidi di parti CNC?

You need to consider several factors when deciding between the two for prototyping your design.

It is very necessary that you have knowledge about many factors. So that you can easily decide that which technology you select for prototyping the design.

One most important fact about 3D

3D printing is basically an additive manufacturer and it can make complex geometrical designs.

But they are very costly.3D printing also conquers CNC machining in the condition of need a rapid turnaround. So, 3D printed prototype products and parts can make rapid prototype in not many days.But it really depends on the company for which you produce prototypes.

The biggest factor about 3D

3D printing is really effective for small volume of production. It is best for small production of Prototipo rapido di parti CNC. It is also reallybeneficent for low budget.

CNC machining:

CNC maching is highly affordable for larger volumes of products. And it is also very low cost for big projects.

On the other hand, if your target prototype consists of 100 prototypes then switch to injection molding. Because it is best for larger volumes of production.CNC machining is also very effecient for complex designs.

Furthermore, it is best technology for rapid prototyping. CNC machining is best when manufacturers need perfect dimentions. And it also uses materials with higher mechanical properties in comparison to 3D printing.

Drawback of CNC machining

A drawback of CNC machining is usually a little pricier to produce Prototipo rapido di parti CNC. But in the condition when manufacturers need to make prototypes of distinct designs, 3D printing is best choice. 3D printing is more competent and much superior.

Quick summary of CNC machining and 3D printing:

| Stampa 3D | CNC machining |

| 3D printing is an ideal choice when engineers need to save money for small projects. | CNC machining is a best choice for average to high volumes of projects. |

| And it is also very effective for complicated designs. | Engineers think that it is better for exactness and repeatability. |

| It can produce complicated geographical designs of Prototipo rapido di parti CNC. | It also provides best finish of your targeted project.

|

| But it is very costly for complex designs. | Most engineers believe that CNC machining is like a piece of cake. As it does not require lots of training and researches to start with it. |

| It is a truth that CNC machining is highly accessible. But you can say that it is very helpful to understand and proceed by using it. |

What are some qualities of a good prototipi rapidi di parti CNC?

A perfect prototype has the ability to improve even at last stage of final design. And it is also very reliable for mass production. Manufacturers can easily validate even in the final version.

Furthermore, by prototyping you can easily reach on a level that is nearer to the level of perfection. You can easily judge the abilities of your final design by prototipi rapidi di parti CNCcompany.