2020 년에 플라스틱 사출 제조업체를 고용하는 데 드는 비용은 얼마입니까?

플라스틱 사출 성형 기술의 가장 인기있는 이점

플라스틱 사출 제조업체 기술 소개

플라스틱 사출 제조 는 플라스틱 제품 산업에서 매우 유명합니다. 모든 산업은 여러 플라스틱 제품을 사용합니다. 마찬가지로 인간 활동의 범위도 이와 관련이 있습니다. 건축 자재 및 가전 제품에서 주방 용품에 이르기까지 플라스틱 사용.

다양한 제품을 제조하는 가장 일반적인 방법 은 플라스틱 사출 제조업체 기술입니다. 또한 최신 장비는 생산 프로세스를 자동화 할 수있는 기회를 제공합니다.

최소한의 투자로 단시간에 우수한 기술적 특성을 가진 제품을받을 수 있습니다. 폴리머 제품은 재활용이 가능합니다. 따라서 환경 친화적 인 소재입니다.

플라스틱 사출 제조업체 성형 절차는 무엇입니까?

사출 성형은 하는 제조 공정 입니다. 그 위에 고르게 분포되어 고형화됩니다. 결과적으로 이것은 플라스틱 제품을 대규모로 제조하는 가장 일반적인 방법입니다.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to 플라스틱 사출 제조 molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

플라스틱 사출 제조 application for injecting technology

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced 플라스틱 사출 제조 technology:

- enclosures for electronic equipment;

- automotive components;

- plastic caps and caps;

- cases for medical equipment;

- household appliance parts;

- Kids toys;

- plastic packaging, etc.

Benefits of 플라스틱 사출 제조 molding technology

Many 플라스틱 사출 제조 choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

Why is it recommended to choose 플라스틱 사출 제조 in making large batches?

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

As a result, 플라스틱 사출 제조 can get both simple and very complex product, with many holes and bends.

The minimum need for machining the product. More often than not, the finished product does not require any processing. Moreover, exceptions are very complex products. However, in this case, the improvements are minimal.

무제한 완제품.

The metal mold, which is created before production, will last a very long time. Subsequently, with its help you can make any number of products.

대량 생산에 따른 저비용.

The more products will be manufactured, the cheaper the cost of one copy. Because the main budget is spent at the stage of preparatory work. Hence, it is carried out only once.

At the same time, 플라스틱 사출 제조 technology has its drawbacks.

- the high cost of preparatory work, and

- accordingly, the unprofitability of manufacturing a product in a single copy or in a small batch.

THE MAIN STAGES OF THE PRODUCTION OF THE PRODUCT BY INJECTION MOLDING

The process of manufacturing plastic products by injection molding involves several stages. Generally, it can be divided into two groups:

- preparatory work and

- casting itself.

Let’s consider these stages in more detail.

Preparatory work

Creation of 3D models of the future product. You can create a 3D-model according to the drawings, description or photograph. Three-dimensional modeling is carried out in a special program by an experienced specialist.

Prototype manufacturing.

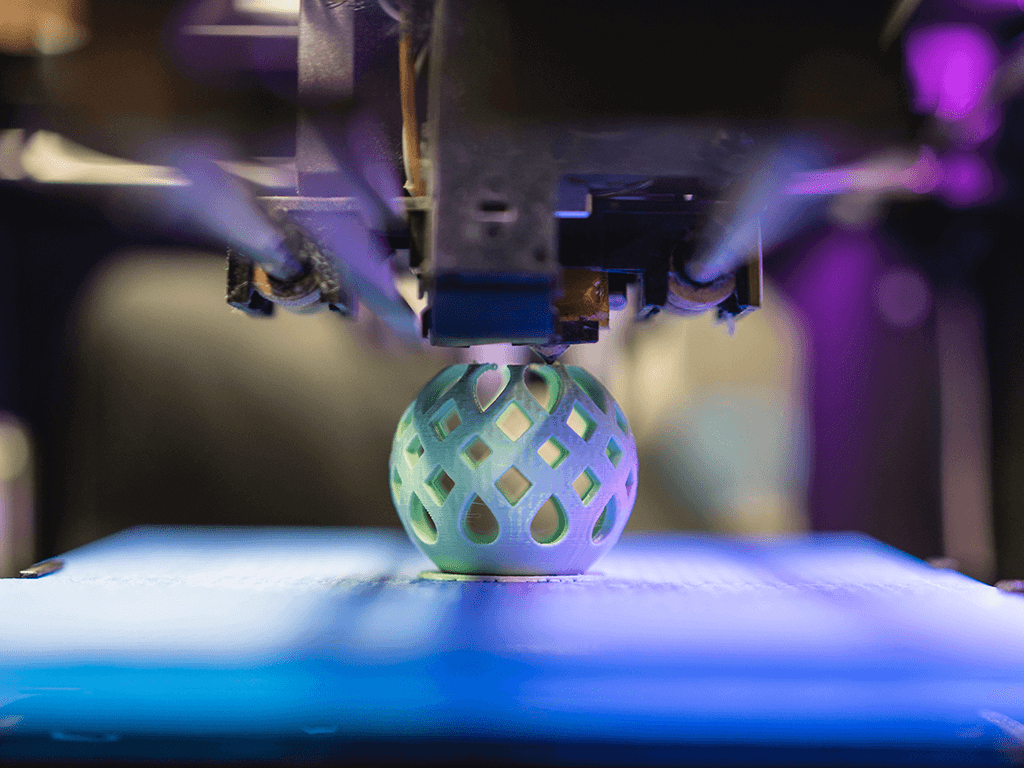

3D 모델을 만들고 승인 한 후에는 프로토 타입, 즉 미래 제품의 샘플을 만들 수 있습니다. 이것은 대부분 3D 프린팅을 사용하여 수행됩니다.

향후 제품을 평가하고 테스트하려면 프로토 타입이 필요합니다.

부정확 한 부분이 발견되면 첫 번째 단계로 돌아가 3D 모델을 완성해야합니다.

금형 설계.

이 프로세스는 향후 제품의 3D 모델을 기반으로합니다. 설계 할 때 플라스틱 사출 제조.

금형 제작.

완성 된 3D 모델은 여러 부분으로 나뉩니다. 또한 각 부품은 별도로 제작됩니다. 그 후 그들은 금형으로 조립됩니다.

캐스팅 테스트.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which 플라스틱 사출 제조 should not rush. Because the quality of future products depends on it.

Injection molding process of plastic injection manufacturer

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

- type of plastic

- mold temperature, etc.

- For small items, this is usually a few seconds.

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

What is the cost of plastic injection manufacturer for producing injection mo0lding product?

As a rule, the 플라스틱 사출 제조 by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

- The complexity of theThe higher it is, the more expensive the mold will be, and accordingly, each product.

- Type of plastic. The material is selected based on the requirements for the final product.

- Number ofpieces in a batch. The more of them, the cheaper each product, and other significant factors.

The advantages of plastic injection manufacturer technology

For the production of large batches of polymer products, 플라스틱 사출 제조 technology of plastics is characterized by the advantages of high precision casting. By injecting the molten mass at an increased rate, uniform filling of the mold is ensured, including microscopic holes. Generally, the method is characterized by many advantages, due to which it is popular:

- Possibility of manufacturing products of any geometric shape and degree of complexity.

- Thin-walled parts are made. The complexity of the design depends on the mold.

- Moreover, it has high detail and takes into account all the bends. As well as the holes of the future product.

- No need for plastic injection manufacturer for subsequent machining of parts.

- Similarly, some complex products may undergo minimal processing.

- Mass production of unlimited plastic parts. The life of metal molds is tens of years.

- So, they are used to manufacture a huge number of polymer products.

- Quick payback when organizing the production of a large batch of plastic products. At the same time, the cost of one product is reduced.

- without quality deterioration with an increase in the number of copies produced.

plastic injection manufacturer equipment features

Modern life is not possible without 플라스틱 사출 제조 플라스틱 제품 플라스틱 사출 제조 장비는 고객의 모든 요구 사항을 충족해야합니다. 고품질의 내구성있는 플라스틱 제품 생산에 관심이 있습니다. 요약하면, 장비는 고객의 요구에 맞게 맞춤화되어야합니다.

프로젝트에 대해 도움이 필요하면 0086-769-82821468로 하거나 sales@kaitomould.com으로 .