사출 성형 공급 업체가 올바른 사출 도구를 선택하는 방법은 무엇입니까?

사출 성형 공급 업체 : 올바른 사출 성형 도구 선택

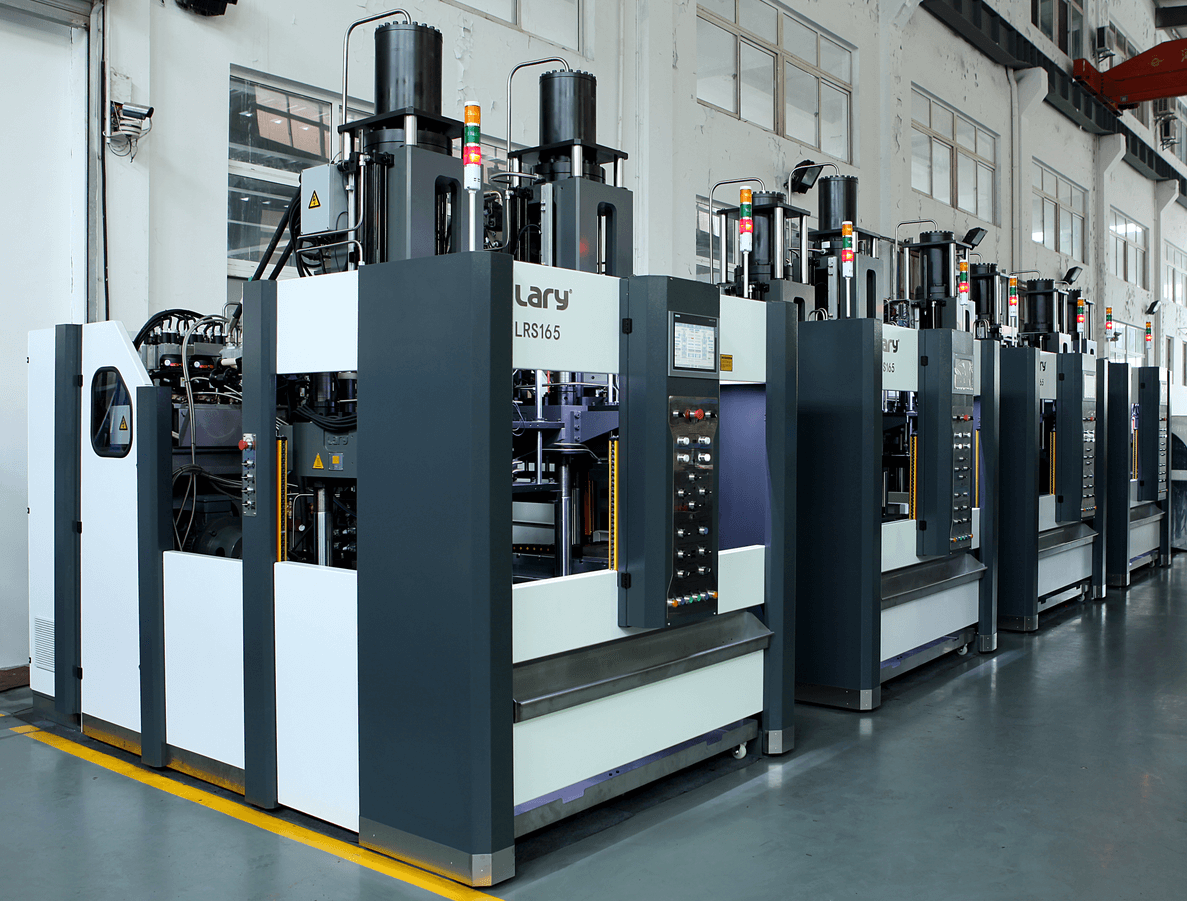

고품질 플라스틱 부품 사출 성형 공급 업체는 올바른 도구를 선택해야합니다. 결국 이러한 도구는 플라스틱 부품의 성공을 보장하는 데 중요한 역할을합니다. 공급 업체는 특히 사출 도구와 관련하여 다양한 옵션을 제공합니다.

However, to make the right decision, you would need to do in debt research. These tools are like cars, you can find them in all shapes, and sizes. You can find several famous brands that produce high-quality tools.

So, to make things easier for you, we are going to provide you a complete guide on choosing the right tool. The tips below would assist you in every possible way.

How to choose the right Injection Tool

Right Model Series

If you have been searching for a moulding machine, you would know that there are many dedicated machines available in the market. After all, manufacturers produce a series of machines dedicated to a certain industry.

So, the first step is to pick a machine that is built according to your industrial needs. In addition, you would have to focus on the raw material. For example, to develop PET bottles, you would be needing a PET Series injection moulding tool.

Injection Weight of IMM

The next most important parameter for choosing the perfect tool is the injection weight of IMM. The right weight of the machine will help you produce the right products. The IMM is expressed via ounze or gram.

Manufacturers often misunderstand the parameter. They confuse it with random machine weight. However, it is way more than. When a manufacturer finalizes the plastic material, it can determine the weight of the desired plastic part.

Once they know the exact weight of the plastic part, they are in a better position to make a decision regarding the injection moulding machine. More formally, we can say that injection molding weight is the maximum plastic weight that an injection device can reach at the time the screws are making the maximum injection stroke. All this happens under the condition of an empty injection.

Remember here, by empty injection, we do not mean injecting into the mold.

The parameters reflect the processing capability of the injection molding machine to a certain extend. It is possible to measure it. However, you can get it via theoretical calculation.

NOTE: There might be a difference of certain degrees in measured value and the theoretical value.

테스트 재료의 경우 1.05 정도의 일반 PS 밀도를 사용해야합니다.

필요한 클램핑 력

플라스틱 부품을 만들려면 용융 된 플라스틱을 금형에 고속으로 주입해야합니다. 고속을 사용하는 이유는 금형 내부에 압력을 생성하는 데 도움이되기 때문입니다. 절름발이 용어로 우리는 금형의 양쪽 절반을 다른 방향으로 밀어야한다고 말할 수 있습니다.

이렇게하면 액체 플라스틱이 칸막이 위로 빠져 나갈 수 있습니다. 따라서 제품에 버 또는 플리스가 생깁니다. 그러나 올바른 클램핑 력을 사용하면이를 방지 할 수 있습니다. 클램핑 력을 kN 단위로 측정합니다.

To right clamping force depends upon the internal pressure of the mold and the product’s project surface area. A good machine generally has a clamping force from 250 kN to 12.00 kN. It is a pretty decent range. It would allow you to manufacture products from 0.5 grams up to 5 kilograms.

Shot Volume

The amount of material that you would need to complete a single production cycle is the shot volume. Make sure that your shot volume is not more than 15 to 80 percent of the maximum melting capacity. Do remember, that the percentage can be different in certain types of thermally unstable plastics.

Following this rule will help you safeguard liquid plastic quality along with the reproducibility of the process.

Required Injection Pressure

Injection moulding suppliers need to make sure that your injection pressure tools should have come with adjustment of screw-cylinder. An adjustable screw cylinder offers the facility of making changes to pressure and speed during the injection phase.

Thus, it increases the facility for accommodating different requirements.

Available Capacity

Sometimes it is important to dedicate a machine to a certain type of products. The reason being, these products are in high demand. You need to deliver a large volume of these parts every year. Assigning them a dedicated machine would make the production process efficient.

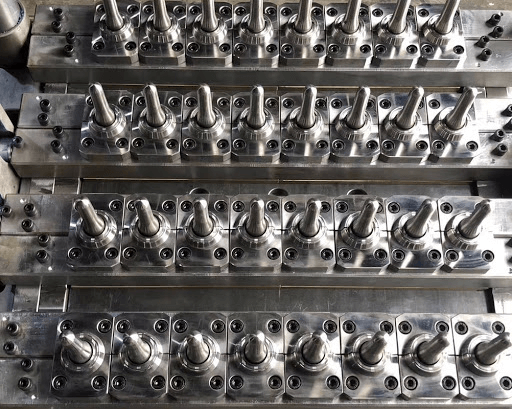

Mould Dimensions

Injection moulding suppliers need to pay extra attention to the dimensions of the mold. It is imperative to check these dimensions all the time. You need to focus on the width and length. In addition, pay close heed to the height of the mould.

Make sure that the mould and the machine have the capacity to open up twice the height of the product. This would ensure easy access to the product while removing it from the mold. You can call this opening as the “daylight opening.”

In addition, you need to leave some space for the optional use of a robot. Certain production processes sometimes use a robot. Last, but not the least, you need to see if the machine requires tie bars. The tie bars have a direct impact on the usable part of the floor plate. Thus, it would affect the machine size.

Cycle Time

효과적인 사출 성형 도구를 선택할 때 사이클 시간도 고려해야합니다. 이것은 중요한 사실이며 생산 과정에 직접적인 영향을 미칩니다. 사이클 타임이 짧은 제품에는 스프린터가 필요합니다.

단거리 선수는 고가의 기계이지만 매우 중요합니다. 그 이유는이 기계는 매우 빠른 사출 성형을 제공하기 때문입니다.

코어 풀러

스마트하고 효과적인 사출 성형 기술에는 여러 개의 공압 또는 유압 슬라이더가 필요합니다. 이러한 각 동작에 대해 기계에는 개별 코어 풀러가 필요합니다. 간단히 말해서, 사출 성형기가 제어 할 수있는 동작 수는 보유하고있는 코어 풀러의 수와 같습니다.

모든 슬라이더를 제어하려면 기계에 각각의 풀러 수가 있어야합니다. 따라서 올바른 수의 코어 풀러가 있는지 확인하십시오.

로봇 핸들링

플라스틱 부품은 모양을 유지하는 경향이 있지만 완전히 견고하게하려면 플라스틱이 완전히 식을 때까지 기다려야합니다. 특히 부품이 완전히 냉각되지 않은 경우 사출 중 제품이 손상 될 수 있습니다.

따라서이 특정 문제를 방지하려면 로봇 공학을 사용하여 개입해야합니다. 로봇 팔을 사용하여 금형에서 컨베이어 벨트로 제품을 옮겨야합니다. 따라서 선택한 도구에 로봇 팔을 통합 할 수있는 옵션이 있어야합니다. 사출 성형기 근처에 로봇을위한 충분한 공간이 있어야합니다.

기계의 공차

기계의 공차는 압력을 견딜 수있는 능력을 정의합니다. 부품 설계는 허용 가능한 공차를 나타냅니다. 따라서 주어진 치수가 표시된 공차보다 더 많이 벗어나지 않는지 확인하십시오.

The tolerances factor does have a great impact on the choice of injection molding tools. For example, you can have extremely low tolerances to develop high precision parts.

Final Words

Injection molding tools have a direct impact on the product design, production, and quality. Therefore, it is critical that you have the right and high-quality machinery. To choose the right tool to consider the tolerance rate, cycle time, core pullers and among other factors.

With the help of these factors, you will be able to make the right decision. You will be able to choose a machine that is not only dedicated but also efficient and effective. It will yield the desired results. After all, the main objective of experienced 사출 성형 공급 업체 is to incorporate the latest market trends and technology to achieve fine and sophisticated products.

프로젝트에 대해 도움이 필요하면 0086-769-82821468로 하거나 sales@kaitomould.com으로 .