Aluminium Die Casting Vs Kaedah Pembentukan Aluminium Lain

Aluminium Die Casting Vs Kaedah Pembentukan Aluminium Lain

Apakah Teknik Aluminium Pemutus yang berbeza

Proses aluminium die casting adalah proses serba boleh. Ia membolehkan penciptaan bentuk yang kompleks, namun kuat dan cekap. Aluminium itu sendiri adalah aloi yang hebat untuk pembuatan prototaip dan produk. Populariti bahan telah menyebabkan sejumlah teknik lakonan.

Setiap teknik ini menawarkan faedah yang berbeza. Pada masa yang sama, mereka datang dengan had mereka. Walau bagaimanapun, adalah penting bagi setiap jenis lakonan untuk memberikan hasil yang baik. Dalam artikel ini, kita akan membincangkan kaedah pembentukan aluminium yang berbeza.

Oleh itu, tanpa berlengah lagi, mari kita mulakan!

Kaedah Pembentukan Aluminium yang berbeza

Proses pembentukan aluminium yang paling biasa merangkumi yang berikut

- Bergolek

- Penempaan

- Penyemperitan

- Pemutus

Untuk sebarang jenis logam, pemutus adalah proses pembentukan yang paling serba boleh dan berkesan. Adalah mungkin untuk membuat beberapa bahagian yang terbaik, kuat dan kukuh menggunakan teknik ini. Menurut anggaran Jabatan Tenaga AS, kira-kira 90 peratus barang yang dihasilkan mempunyai produk besi tuang.

You can apply the same casting technique for aluminum that you would use for other metals. But the most common methods include the Die Casting, Green Sand Casting, and the permanent Mold Casting.

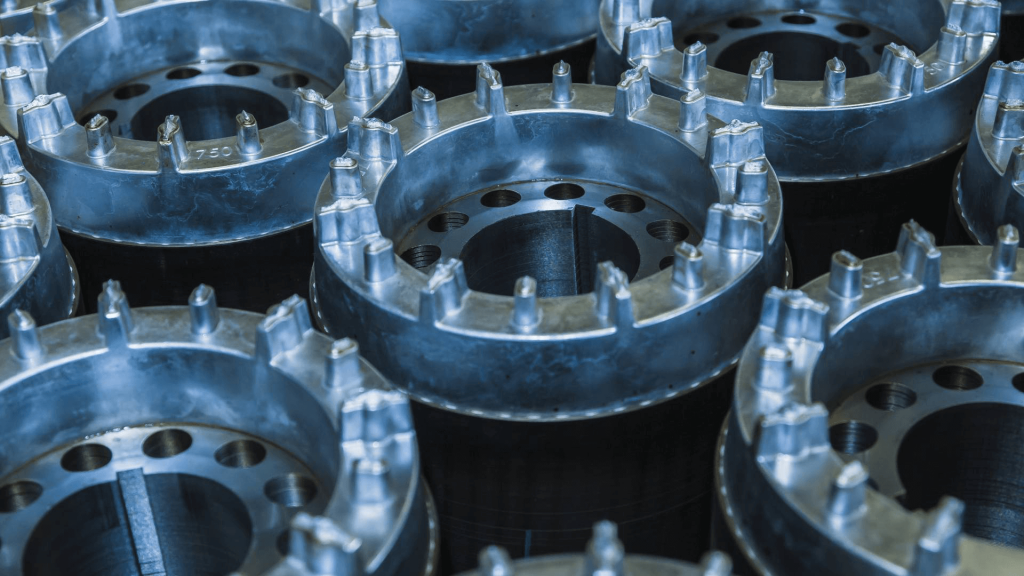

Permanent Mold Casting

Permanent mold casting is among the most common technique for molding metals. It creates a reusable metal mold at an extremely high temperature. When the manufacturer wants to cast-aluminum the mold either should be of steel or gray iron.

The molds two halves are first connected and then they are pre-heated. Once they reach a certain temperature, then its time to pour the molten metal. The metal enters the mold via a ladle. Once the mold is full, give it some time to set and solidify.

After it solidifies, remove it. It is important to take the casting out of the mold as soon as it solidifies as the inflexible mold can result in defects in the casting. After removing the casting, the process is repeated instantly.

Permanent Mold Casting: Advantages

It is possible to recoup the initial tooling cost because of the mold’s reusability. Manufacturers are able to generate high-volume runs using the same mold over and over again.

You do not need of preparation between casting.

The technique offers a high repeatability rate.

With permanent casting, it is possible to achieve high dimensional accuracy. However, for accuracy, you need to have accurately machined mold.

Permanent Mold Casting: Disadvantages

The initial tooling cast is fairly high especially when you compare it to other casting techniques.

The molds are inflexible. Thus, it can lead to defects in casting if they are not removed on time.

In the case of large runs, you may have to replace the permanent mold as they have a short lifespan.

Green Casting Aluminium

Another effective technique for casting aluminum is the Greensand casting. The technique uses clay-bounded, moist sand to create the mold. The first step to packing sand around the desired pattern in order to create the mold cavity.

After that, it is time to remove the pattern. Then, the manufacturer places the mold into a brace. At this stage, the cavity is paired with its other half. This part is similar to that of the permanent mold casting. Once the mold is ready, it is time to pour the molten metal into the cavity.

Sekarang, tunggu casting menjadi kukuh. Untuk membuang pemutus, pengeluar memecahkan acuan. Langkah ini berbeza dengan acuan kekal, di mana, mungkin untuk menggunakan semula acuan. Untuk menyelesaikan proses casting, gilingkan ciri-ciri yang tidak diperlukan seperti riser dan tab.

Sebilangan besar kemudahan dapat menggunakan semula sebahagian besar pasir yang digunakan dalam proses pemutus ini.

Pemutus Greensand: Kelebihan

Teknik ini menawarkan kepelbagaian dari segi ukuran dan berat badan. Adalah mungkin untuk membuang hampir semua bahagian menggunakan pemutus Greensand.

Bahan dan kos perkakasnya sangat rendah.

Greensand Casting: Kekurangan

Setiap masa, anda memerlukan acuan baru kerana prosesnya memerlukan pemecahan acuan sebelumnya untuk membuang coran.

Permukaan pemutus tidak begitu licin. Anda mungkin perlu melakukan kerja tambahan di atasnya.

Teknik ini tidak menawarkan ketepatan dimensi.

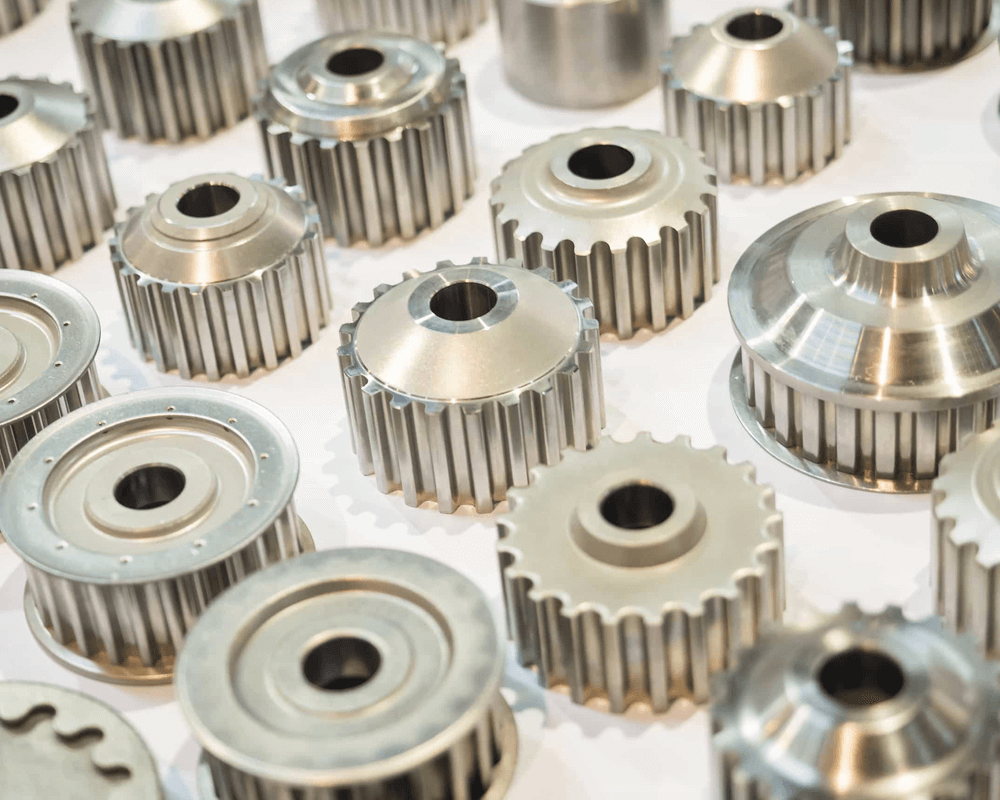

Die Casting Aluminium Process

The die casting Aluminium process is similar to that of the permanent casting. Both these techniques reuse the metal mold instead of disposing of the mold as it is the case in Greensand casting. In die casting, the molten metal injection takes place at high temperatures.

Due to the high pressure, the casting is able to have a better surface finish and it has greater details. However, if not being careful, the injection can lead to a trapped pocket of air. This would have an adverse impact on the durability of the die casting.

Manufacturers would recommend die casting aluminium for mass production of small size parts.

NOTE: The complexity of the process is limited.

Due to the configuration of the die casting apparatus, the manufacturers have limited choices in terms of cores. As the configuration does not allow a variety of cores to be inserted.

Die Casting: Advantages

With die casting it is possible to cast parts that have superior detailing and surface finish.

Dies that are created using high-grade tool steel have a longer life. They are robust and sturdy.

Die Casting: Disadvantages

The technique offers limited complexity especially when the products have hollow sections.

The initial tooling cost is extremely high.

The strength of the mold can be compromised due to defects such as porosity.

Casting Aluminum Methods: Comparison

| Labor Cost | Initial Cost | Typical Tolerances | Typical Volume | Surface Finish | |

| Permanent Mold | Low | High | +/- .01 — .03 in. | Medium-High | Good |

| Die | Low | Very High | +/- .01 — .015 in. | Very High | Very Good |

| Greensand | Low | Low | +/.01 — .06 in. | Low-High | Average |

Take Away

There are different methods for casting aluminum, but the most common one is the die casting aluminium technique. This method is highly effective and efficient. It yields projects that do not require additional work after being cast.

Although the initial tooling cost is high, it is possible to reuse the molds. Thus, this is compensation in terms of cost. What more is that the technique has a low labor cost and great tolerance.

We offer the best die casting services. Reach out to us today and learn more about our services.