Empat Langkah Mudah Untuk Membuat Bahagian Plastik Prototaip

Langkah-langkah Berkesan Untuk Memastikan Kualiti Bahagian Plastik Prototaip

Terdapat beberapa prasyarat yang diperlukan agar bahagian atau produk plastik dilancarkan di pasaran. Contohnya, fungsi produk, estetika, dan banyak lagi. Anda mencapai semua ini dengan usaha yang minimum, pengeluar bergantung pada bahagian plastik prototaip. Mereka dapat menyelesaikan hampir semua kesalahan sebelum memperkenalkan produk di pasaran.

Prototyping is the best way to approach all quality control-related problems. It would make sure that the parts and components are of top-notch quality. With prototyping, it is possible to cut down the time to market.

For this purpose, we are going to talk about the simple steps of the injection molding technique and its impact on the plastic prototyping industry.

The Making of Prototype Plastic Parts

Injection Molding

Among the different prototyping processes, injection molding is the most prominent prototyping technique for plastic. It is effective for creating all types of plastic prototypes. This plastic prototype then acts as the basic guide for the manufacturer to follow during the mass production phase.

Dengan adanya prototaip, pengeluar dapat memastikan bahawa idea mereka bukan sahaja mempunyai kesahan, tetapi juga sesuai. Produk yang mereka lancarkan mempunyai beberapa kegunaan di pasaran. Selanjutnya, mereka dapat mengambil maklum balas masa nyata dan membuat perubahan yang diinginkan dalam produk dengan kos minimum.

Mereka dapat mengenal pasti hampir semua kesilapan yang berpotensi, sehingga dapat mengurangkan risiko masalah setelah anda melakukan pengeluaran secara besar-besaran. Bagaimanapun, kesalahan yang dikenal pasti selepas pengeluaran besar-besaran bukan hanya memakan masa untuk membetulkannya, tetapi juga sangat mahal. Ini adalah sesuatu yang cenderung dielakkan oleh pengeluar dengan apa cara sekalipun.

Penggunaan Perisian Citra 3D

In most cases the pengeluar use 3D animation or imagery software to create the design. After they finalize the design on the computer, the next step is to replicate the same design using ABS plastic. For this purpose, they either use a 3D prototyping mold or a 3D printer.

NOTE: Manufacturers might not use the actual material required for the final product for prototyping. The main objective here is to give clients the feel and look of the product for better understanding.

Once, the manufacturer and client see the product prototype in person, they would be better able to make changes to it. They would know actually what things require to enhance and what needs to be eliminated. It is possible to expose the design flaws via prototyping.

Injection molding prototyping is the biggest step in the product control process. It ensures that the product is according to the requirements and it also oversees its creation process.

Make a Plastic Product Design

Creating a design or concept is the first step in manufacturing. Regardless of what they are manufacturing, may it be a packing product, an electronic device, or a garment, you need to have the basic design. This step is no different in terms of plastic parts.

When you are creating the design for plastic parts, you need to pay heed to its functionality and the feasibility factor. It is equally important for the idea to be doable. If the idea does not have any use in the real world, it is simply a waste of money and effort.

To ensure the success of your product, you can either reach out to professional experts for help, or you can rely on 3D prototyping techniques. Collaborating with the experts would be fruitful. Just make sure that you do not have any communication gap.

You should provide them with as much information as possible regarding your idea. There are different formats that you can use to create the digital file of your concept. For example, you can go with the stl file or the stp file. To create these files, you would be using different CAD software.

If you are looking for something easier to present your idea in an effective manner, try using animated videos or slide shows.

Prototype Plastic Parts Product Engineering

At this point, everyone has approved the product design. It has even cleared the functionality standards and everyone believes that idea is doable. It is time for the product engineers to step in. To create your plastic product, the engineers would search for the requirements of prototype plastic parts.

The prototype plastic parts manufacturers use steel tools for the prototyping purpose. Therefore, it is important to taper the material in order to ensure a seamless and smooth injection. For instance, you need to have the right thickness for the part’s wall. There should no be undercuts.

Semua ini penting kerana ia akan mengelakkan bahagian keluli melekat pada satu sisi alat, atau retak. Pengilang berpengalaman menemui pintu yang perlu disuntik plastik. Selain itu, mereka akan menilai bahan plastik di dalam gerbang.

Mereka juga dapat menyesuaikan ketebalan dinding untuk memastikan aliran bahan yang betul dan lancar ke seluruh pintu gerbang. Tidak akan ada pembaziran dari segi limpahan. Pengilang menyedari faktor-faktor yang boleh membuat keseluruhan proses menjadi tidak kemas seperti udara yang terperangkap. Oleh itu, mereka akan berusaha sebaik mungkin agar proses berjalan lancar.

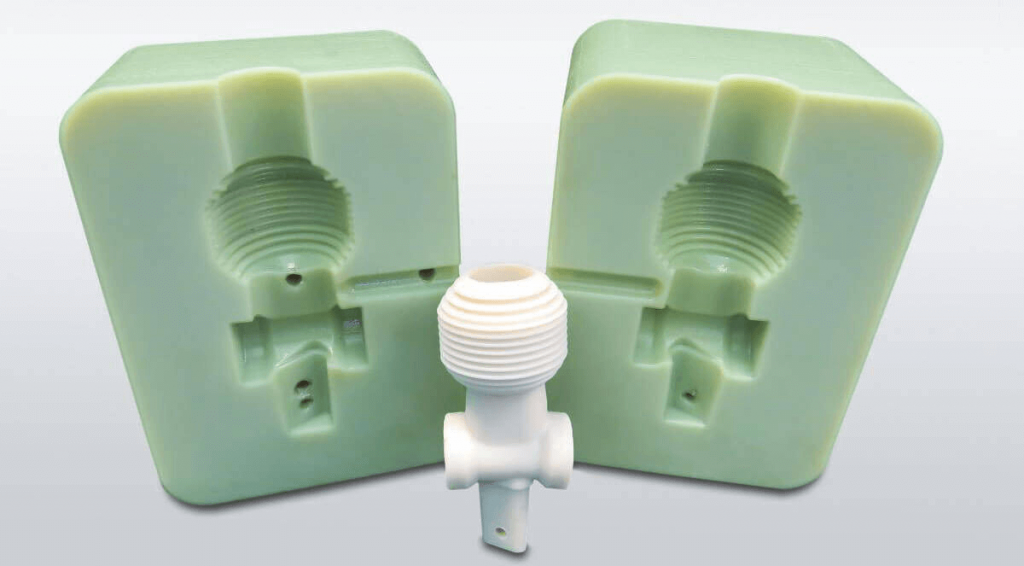

Penciptaan Acuan untuk Bahagian Plastik

In the prototype plastic part manufacturing, the creation of the actual mold is the most vital process. Since the ideas and the concepts are fully engineered, it is time to step towards the creation of the actual mold. The injection mold technique uses plates to push a part of the mold, while there are water lines that responsible for the cooling process.

In the case of complex and complicated design, the engineers would require steel tools along with other pieces. Moreover, with technological advancement, there are other effective ways to create molds.

Using Injection Molding Machines for Plastic Parts Prototyping

Sebaik sahaja anda membuat acuan, langkah seterusnya adalah meletakkan acuan ke dalam mesin cetak suntikan . Mesin ini kemudian akan menggunakan acuan untuk membuat prototaip. Prosesnya melibatkan suntikan plastik cair sementara 2 bahagian acuan dipegang bersama melalui pengapit melalui tekanan yang melampau.

Tekanan ini berbentuk hidraulik. Oleh kerana bahan memaksa masuk ke dalam acuan, saluran air akan menyejukkannya. Oleh itu, menghasilkan pemejalan cepat.