How to improve Rapid prototyping 3d printing in simple 3 steps?

Simple rapid prototyping techniques and process guide

One of the main elements that characterized our blog was the innovation brought by Rapid prototyping 3d printing. It got famous in the various areas. For instance:

- Medicine

- Technology

- Society and art

It was the recurring element in each of our articles. But with this in-depth analysis, I wanted to focus on something more concrete. It is, on what advantages and disadvantages this wave of innovation could tangibly bring. Especially within companies and therefore in production.

Rapid prototyping 3d printing Introduction

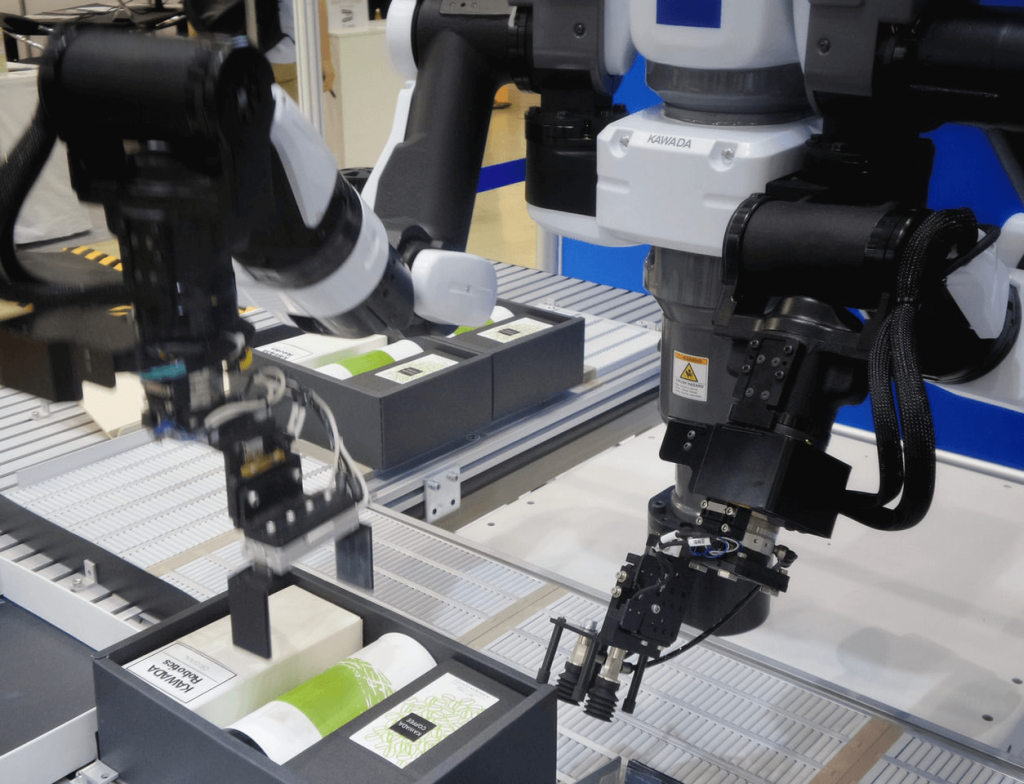

The rapid prototyping 3d printing is considered by many as the bearer of a new industrial revolution. It is also setting the stage for the creation of an economic model. It is based on ‘ self-production.

Moreover, it identifies users, freeing itself from the classic passive role. Furthermore, it will take one more active in the process involving the:

- Creation

- distribution and

- consumption phase

There are many rapid prototyping 3d printing advantages that a company enjoys. Therefore, we can elaborate it from various perspectives. Now rapid prototyping manufacturers around the globe are able to make low cost products. Hence, the whole procedure is possible in very short time.

It is important to underline that 3D printing does not totally replace conventional production methods. Because, it does not reach significant economies of scale.

It is also highlighted how a customization model shared between the company and the consumer. It provides facility to both parties. Whether it is customer or manufacturer both can enjoy two end benefits.

Rapid prototyping 3d printing lead to revolutionize the production system. Today it is possible to prepare a 3D model.

Three False Truths About rapid prototyping 3d printing

There are many false beliefs that circulate about 3D printing and rapid 3D prototyping.

Before you watch helplessly the evolution of your competitors, read here!

- ANYTHING CAN BE REALIZED WITH 3D PRINTING

Many believe that 3D printing is the way to accomplish anything.

FALSE!

With the right printers, the right materials and the right skills you can get both design objects and components. But you can’t do everything!

We must always check whether 3D printing is the best and fastest solution to make a prototype.

- IT COSTS LITTLE AND YOU DO IT IN ONE DAY

Many believe that 3D printing costs very little and that printing three-dimensional objects takes very little time.

NOT ALWAYS!

Rapid prototyping 3d printing, is certainly cheaper and faster. It is better than the traditional methods for creating a prototype or a model.

What they do not know is that there are different materials. A prototype manufacturer can produce product variables according to his choice.

Before being sent to print, a prototype must be engineered. And the engineering of the product is precisely the phase that takes the most time.

- ANYONE CAN USE A 3D PRINTER

Many believe that by buying a 3D printer you can do it all yourself!

FALSE!

You don’t learn overnight to use a professional 3D printer.

It takes time, study, courses and continuous tests.

In short: YOU MUST KNOW IT AND MUST STUDY AND TRY IT.

Creating a prototype without skills by yourself takes years!

But at what price?

IMPORTANT: a rapid prototyping 3d printing process does NOT stop at 3D printing.

You have to deal with silicone molds, sintered resins, laser cuts, milling, etc.

Why rapid prototyping 3d printing?

It is essential for a professional to reduce the production time of a prototype. Simultaneously, rapid 3D prototyping solves the biggest problem of all time.

With the rapid 3D prototyping you leave competitors behind. Moreover, you can produce with “just in time” logics.

Changes applicable without increasing implementation times

- It is essential for a prototypist to stay on budget.

- 3D printing is faster and cheaper than traditional prototyping.

Rapid prototyping 3d printing provides a fair space for customization. You can analyze your errors during various steps.

The development of modern industry has created new market demands. Subsequently, these are related to the optimization of production processes. So, you can focus on the marketing of the product. In short, a manufacturer has enough time for product promotion.

In the face of these needs, the technology linked to 3D printing has proven to be a valid alternative. Moreover, it is better than conventional techniques. Because it is much more convenient in terms of time and costs. With results, linked to product development, it is clearly superior.

The companies need to adopt the techniques of advance rapid prototyping 3d printing.

The combination of these two techniques can reduce production times. Furthermore, they can generate economic savings of up to 70%.

Context data estimate that the sale of industrial and professional 3D printers will grow by 16% in 2017.

-

What is Rapid Tooling?

The creation of prototype models is a particularly important. Moreover, it is delicate phase for production companies. In fact it allows verifying the product result and correcting any problems.

Rapid Tooling is a technique that allows production in much faster times. This is a process that combines traditional production techniques with rapid prototyping.

The advantages

The main advantages found in Rapid prototyping printing are:

- Print speed. Production time is significantly shorter than traditional methods. It reduces the whole process to one fifth of the time used so far.

- Lower costs. Less than 5% of traditional costs. Thanks to the reuse of waste.

- Superior quality of the parts.

- Possibility of customization, creating models that can be modified in shape and geometry.

- More precision. It becomes much more difficult to get the measurements wrong. Printing starts with the CAD drawing data.

Rapid prototyping 3d printing Conclusion

Rapid prototyping 3d printing technologies are able to provide important advantages. Similarly, it also provides better production. But these are mainly related to the creation of objects. These products bring high complexity and limited production quantities.