Dicas de Projeto e Processo do Fabricante de Matrizes de Moldagem por Injeção

A mecânica do fabricante de matrizes de moldagem por injeção

Indústrias ao redor do mundo engajando fabricantes de moldes de injeção para processos de produção em massa. Afinal, a moldagem por injeção é um processo de fabricação confiável e eficiente. É excelente para a produção de peças a partir de materiais plásticos termofixos e termoplásticos.

There has been an increase of 0.9% in the injection moulding industry since 2014. It seems that numbers are on the increase. The reason being, this manufacturing process can produce hundreds even millions of parts without slight variation.

A consumer can enjoy reliability and consistency even in mass production. Injection moulding has become an imperative part of the manufacturing process. Therefore, we are going to provide you with the basics of the injection moulding process.

What is the Injection Moulding Process?

A manufacturing process uses a special technique to produce the part from both thermosetting plastic and thermoplastic materials. The process starts with the design of the product or parts. Industry engineers or designers are responsible for product designing.

Terminado o desenho, vem a formação dos moldes. O fabricante de moldes é responsável por fazer moldes precisos. Eles podem usar alumínio ou aço para desenvolver moldes. Eles também usam máquinas de precisão para garantir a forma exata dos moldes.

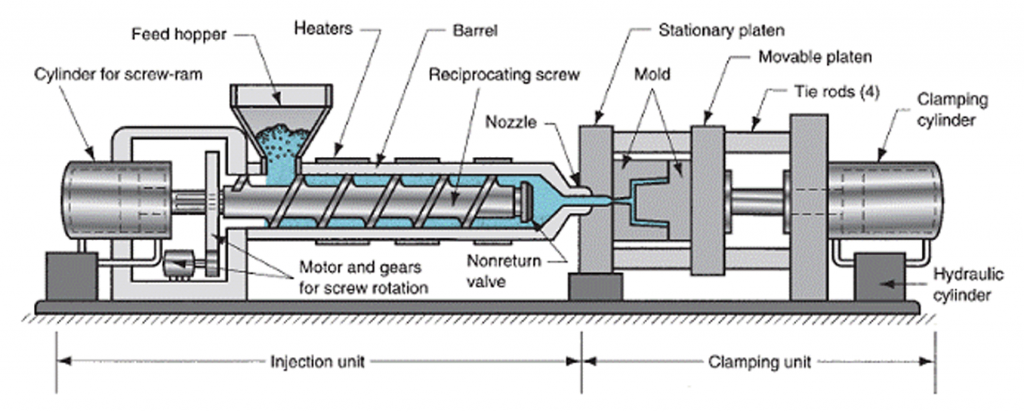

Depois de concluir os moldes, é hora de colocar o material nos moldes. A máquina coloca o material em um barril aquecido. Em seguida, ele mistura o material completamente. Mais tarde, ele força o material aquecido para uma cavidade do molde.

O material permanece na cavidade o tempo necessário para resfriá-lo. Uma vez que o material endurece para a configuração projetada, ele é removido da cavidade do molde. A moldagem por injeção oferece diversidade em termos de fabricação. É possível fabricar pequenas peças, bem como toda a carroceria.

História

Alexander Parkers was the mastermind behind inventing first fabricated plastic. In 1862, during an International Exhibition in London, Alexander demonstrated its material. The named the material “Parkesine”.

Parkesine mainly compromised of cellulose was able to take on any shape. After heating and melting the material, it was possible to mould it in any desired shape. However, it did have some side effects. The material was highly flammable, expensive and prone to crack.

Later in 1872, Alexander and his brother Isaiah came up with an injection moulding machine. The machine was not as sophisticated as we see today.

It had a huge hypodermic need and to inject the plastic it used a plunger. The material first passed through heated cylinders before they reach the mold cavity. It did take some time for the industry to progress. Initially, it produced online hair combs, buttons and collar stays.

However, in the 1940s, the industry rapidly expanded. World War II led to the demand for mass production of products at an extremely low price. Six years later, James Watson Hendry, an American inventor, introduced the screw injection machine.

The machine was an advancement of what Alexander had designed. It was able to better control the speed of injection. The product was also finer. In addition, the machine permitted the mixing of materials. Thus, allowing adding colors to the material.

The mixing made it possible to add the recycled plastic to the virgin material. Today, most injection moulding die manufacturer use screw injection machines. However, these machines are way advance than their ancestors.

The plastic injection industry has made tremendous progress over the years. Thus, we now can enjoy sophisticated machines. From those simple machines, we know have a wide variety of sophisticated injection moulding machines. These machines can produce almost anything.

Different Types of Injection Moulding Process

The basics of the injection moulding process remain the same in every type. They heat the plastic granules until they melt. The melted material is inserted into the mould using high pressure and nozzles. Finally, you wait for the material to cool down and harden in the required shape. Then remove them from the mould.

Abaixo, estão alguns tipos comuns de processo de moldagem por injeção :

- Moldagem por Injeção por Sopro

- Moldagem por injeção de gás

- Moldagem por injeção de reação

- Moldagem por Injeção Multi-estação

- Moldagem por injeção multicomponente

- Moldagem por injeção dupla

- Moldagem por injeção tripla, entre outros

Características do Processo

A seguir, destacamos as principais características do processo.

- Para inserir o material derretido (qualquer tipo de plástico) na cavidade do molde, ele usa um êmbolo do tipo parafuso ou um aríete.

- O resultado t é uma forma sólida e aberta. A forma está de acordo com o contorno do molde.

- O processo pode usar materiais termofixos ou materiais termoplásticos.

- É responsável pela criação de marcas de passagem, jito e uma linha de partição.

- Você encontrará marcas de pinos ejetores, pois estão comumente presentes.

Formulários

Today, the injection-moulding machine can create a wide variety of things. For instance, they are used for producing automotive dashboards, bottle caps, packaging, and spools. They can also produce pocket combs, buttons, and several other plastic products.

Today, automobile manufacturers are a fan of injection moulding manufacturing. It is perhaps one of the most common methods to create car spare parts. In addition, industries around the world use this technique to create different types of parts.

The injection moulding process is excellent for mass production with zero tolerance to error. They can replicate the same product for thousand times without a slight error. It is also possible to use a wide range of materials.

The process is cost-efficient. It has minimal scrap losses and low labor costs. Usually, the finished products require none to minimal finishing after moulding. Nonetheless, the upfront cost of injection moulding die manufacture process is high. The machine is expensive and setting it up requires additional cost.

Usinagem

There are two main methods of creating a mould. Frist is the Standard Machine technique and the second is EDM. Both of these techniques offer great results. However, there are some differences in terms of functionality and usage.

Standard Machining

It is the historical method of creating the injection molds. Nonetheless, technological developments resulted in sophisticated technologies such as CNC machines. The CNC machining was highly efficient. They become an integral part of the injection moulding industry.

They were able to create complex moulds in less time. Despite being created in minimal time, these moulds offered accuracy.

Electrical Discharge Machine (EDM)

Today, the moulding industry has become a fan of the electrical discharge machining process. People often refer to EDM as the Spark Erosion Process. It is perfect for designing complex moulds. In addition, it offers a pre-hardened moulds. Thus, there is no need for heat treatments.

To soften the mould, the manufacturer would need annealing. In order to make changes to the solidified molds, traditional drilling will come into action.

Cost

There are several factors that contribute to the cost of moulds. Some of these factors include part size, cavities, and expected tool longevity. In addition, the injection moulding die manufacturer needs to focus on piece complexity and surface finishes.

Embora o custo inicial seja alto, no entanto, o custo diminui devido à produção em massa.

Vantagens do fabricante de matriz de moldagem por injeção

- É possível fazer a produção em massa de peças com bom acabamento superficial.

- Os fabricantes podem usar moldes metálicos junto com não metálicos para criar peças.

- O processo é econômico para produzir peças pequenas e formas complexas.

- A moldagem por injeção tem a capacidade de manter uma tolerância dimensional próxima.

- É possível usar e reafiar o canal, a comporta e o canal mínimos.

- Possui baixo custo de mão de obra por unidade.

Limitação do processo de moldagem por injeção

- Requer alta potência para operar

- O custo de manutenção é alto.

- As máquinas de moldagem são caras.

- Alto custo da ferramenta.

Leve embora

Injection Moulding die manufacturer offers the convenience and ease. It is possible to design and develop complicated parts in minimal time and limited budget. The modern moulding processes ensure reliability and efficiency.

Modern and skilled manufacturers such as the Katio Mold offer outstanding moulding services. They use state of the art technology and modern technique to produce high-quality parts. Therefore, you should reach out to them. You can effortlessly reach out to their learned customer care staff at 0086-768-82821468. They will resolve all your troubles and queries.