Producător de prototip 3D: Ghid de recomandare a materialelor

Producător de prototip 3D: Ghid de recomandare a materialelor

Ce materiale ar sugera un producător de prototip 3D?

Alegerea materialului este la fel de importantă ca producătorul prototipului 3D. Prin urmare, trebuie să aveți informații complete cu privire la gama largă de materiale disponibile pentru serviciile de imprimare 3D . Fiecare material are propriile beneficii și costuri.

În acest curs al articolului, vom vorbi despre diferita gamă de materiale disponibile.

Introducere în diferite materiale de fabricare a prototipurilor 3D

While choosing the right material for your product, you will have to consider the following aspects.

The Price

This is perhaps the most important phase for you. You need to look for ways to reduce the cost while improving the manufacturing process quality. For instance, if your final part needs to be of metal, creating a prototype with plastic would turn out to be eventful.

Of course, for initial prototypes, you can use plastic as it would cost you less. However, for the later or final prototypes, use the same material as the final product. In this case, it is metal. Instead of going with just one material, we recommend choosing a combination of materials to find the most optimal solution for your prototyping requirements.

Material Quality and Accuracy

The main reason for creating a prototype is to test idea validity and to find errors in it before entering the mass production phase. With a 3D prototype, you can spot the last error in the project. Doing this will give you an excellent overview of your project.

A functional prototype would help identify issues and let you know whether the idea was worth the shot or not. If you are aiming for a complex object or product, that has an elaborate design, you need to focus on the material.

Also, check the 3D printing technique, make sure that it is precise enough to assist you in achieving your goal. It is obvious that you will need to keep the mechanical properties of the material in mind as well. After all, these properties should be compatible with your application.

Când utilizați materialul potrivit și tehnica corectă de prototipare 3D, veți putea produce un obiect de înaltă calitate, precis și complet funcțional. Câteva alte întrebări importante care vă vor ajuta să alegeți materialul corect includ:

- Este important ca prototipul să aibă aceeași greutate cu cea a produsului final?

- Prototipul trebuie să aibă aceleași dimensiuni?

- Ar trebui să aibă aceleași aplicații?

Trebuie să răspundeți la toate aceste întrebări înainte de a lua decizia finală.

Ghid de proiectare a materialelor pentru producătorul de prototip 3D

Deoarece fiecare material are propriile orientări, prin urmare, va trebui să verificați toate aceste ghiduri pentru a lua decizia corectă. Poate că acesta este motivul pentru care unele fișiere 3D nu sunt imprimabile 3D. Trebuie să aveți cunoștințe complete în ceea ce privește geometria și dimensiunea proiectului.

Lack of proper dimensions could lead to different problems. For example, if the walls turn out to be extremely thin, the printer not might be able to print it or it might break. This would lead to counterproductive.

The Best Printing Materials

We have said this before, and we are saying this again. The choice of your 3D printing material majorly focusses on the application requirement. Below, we have come with a selection of materials that a 3D prototype manufacturer would prefer.

Nylon PA12

The first and perhaps the most common material is the Nylon PA12. The white material offers a number of mechanical properties while ensuring the affordability factor. The material is an excellent choice for both productions as well as prototyping. It is made using a fine polyamide powder.

Manufacturers would use the Selective Laser Sintering technology to create the desired components and parts. With Nylon PA12, you also have numerous options in terms of finishes and final touching. However, if you prefer the raw look, you can even have the raw parts.

In addition, to be extremely affordable, the Nylon PA12 gives freedom when it comes to geometry. It goes through several iterations.

Multi-Jet Fusion PA12

This is another amazing material for prototyping. It is grey plastic that lets you create even complex and complicated prototypes. The material is the perfect choice for both the production as well as the prototype manufacturing.

The reason being, it is extremely cheap in its raw form. You will be able to make several iterations without adding a lot to your prototype budget. A reliable 3D prototype manufacturer would recommend this product, especially when you are running low on budget, but don’t want to compromise on quality.

What more is that the objects created using Multi-Jet Fusion PA12, are suited against abrasion and scratches. Therefore, it is an excellent material for testing purposes as well. The material is lightweight, it is weather stable, U.V. stabilized. In short, is the perfect choice for prototypes that are to be tested outdoors.

Prototyping Resin

Materialul este alegerea perfectă pentru crearea de prototipuri detaliate și detaliate. Cu toate acestea, rețineți că nu are capacitatea de a crea prototipuri funcționale. Materialul asigură un finisaj neted al suprafeței și un aspect complet.

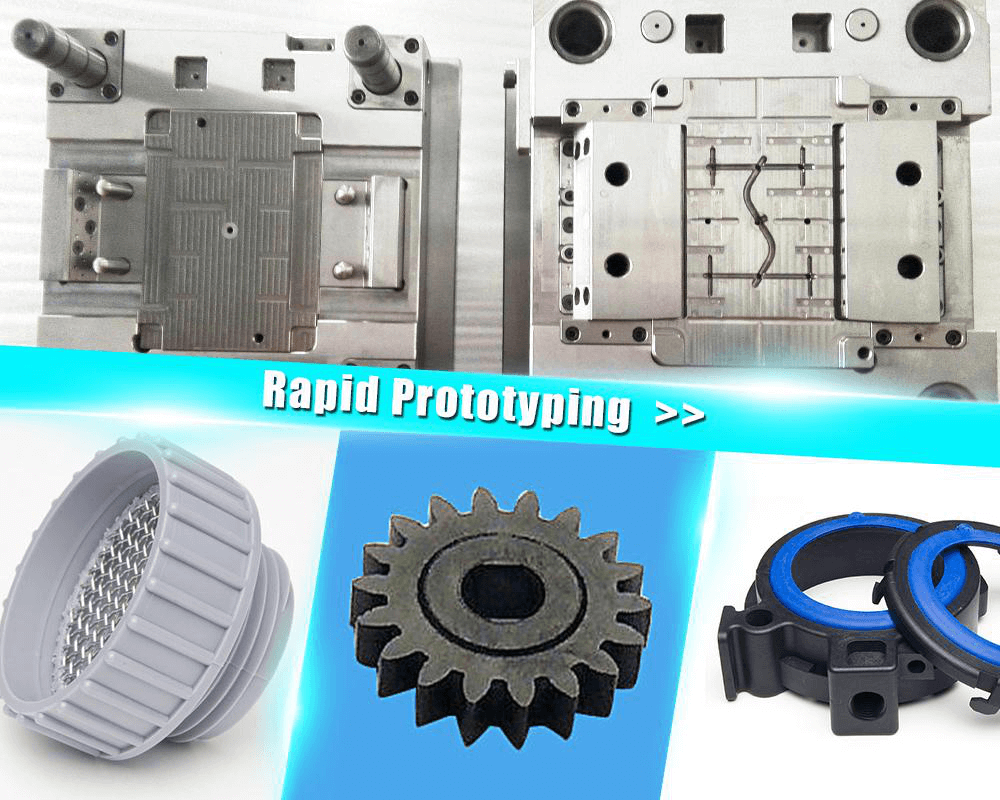

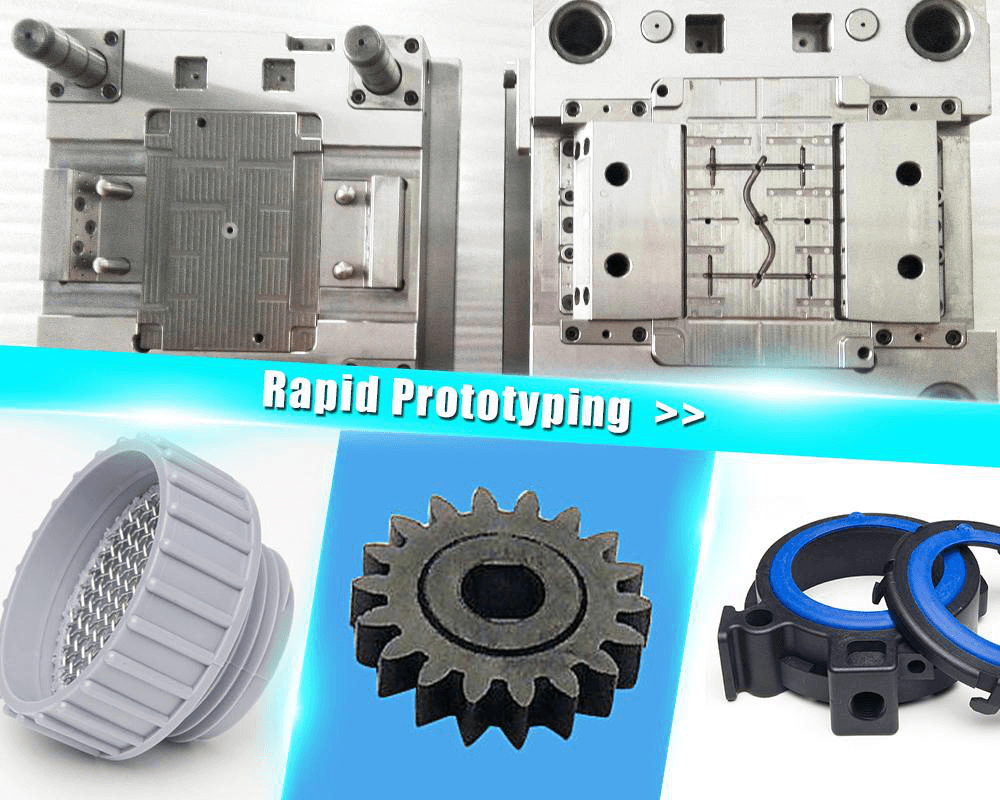

Obiectul care este creat folosind acest material este similar cu cel creat folosind tehnica de turnare prin injecție a plasticului. Pentru a crea prototipuri folosind acest material, un producător de prototip 3D ar folosi procesul de stereolitografie.

PLA

Numeroși producători se bazează pe tehnica de modelare Fused Deposition pentru crearea prototipurilor.

NOTĂ: Opțiunea nu vă va oferi un prototip detaliat.

Dacă aveți un proiect supradimensionat, acesta poate fi o alegere bună. Cu toate acestea, vă recomandăm totuși să consultați producătorul înainte de decizia finală.

TPU

If you are searching for something extremely flexible while being robust, TPU is the solution. The rubber-like material is an excellent choice for creating fully functional, flexible, and sturdy prototypes.

The material would create prototypes that can resist fatigue and stress to a great extent.

3D Prototype Manufacturer: Why US?

At Kaito Mould, we have highly skilled designers and engineers who would create high-quality, accurate, robust, and strong prototypes in no time. In addition to creating prototypes, we would provide you with complete assistance at every step, starting from idea analysis to final production.

To reach out to us today, Click Here.