5 лучших стратегий быстрого прототипирования деталей с ЧПУ для начинающих

Что такое ЧПУ и быстрый прототип детали с ЧПУ?

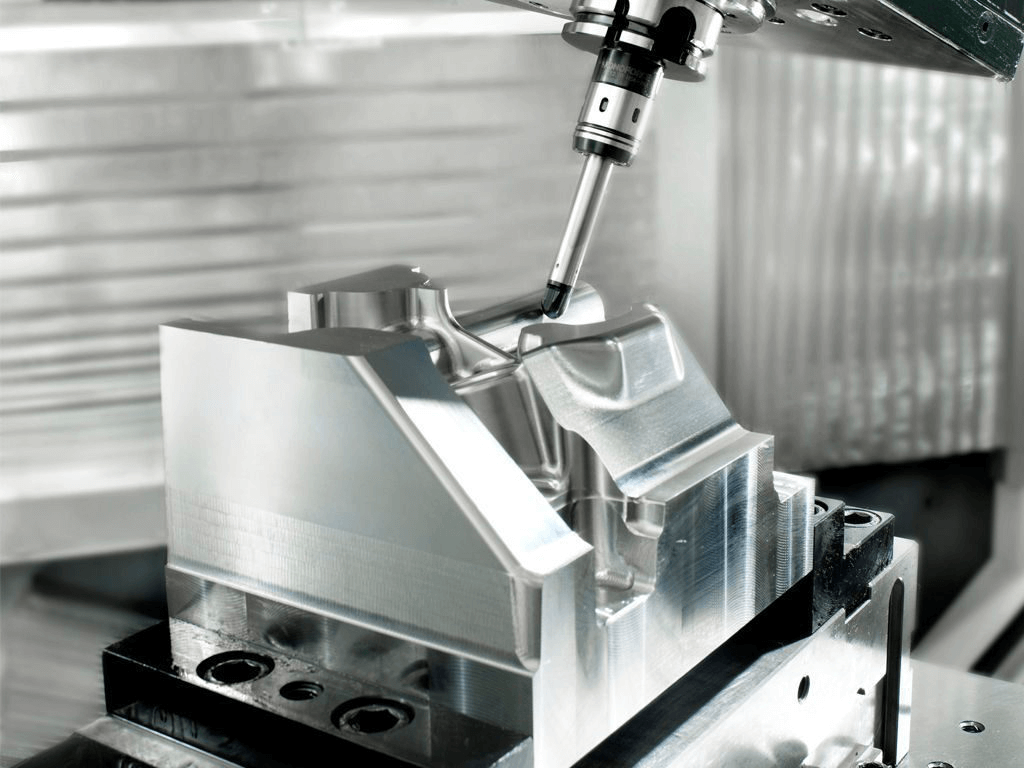

Быстрый прототип деталей с ЧПУ фактически был создан с помощью станков с ЧПУ. И инженеры объясняют, что ЧПУ на самом деле является сокращением от Computer Numeric Control. По сути, это набор машин. Он быстро создает прототипы.

Кроме того, инженеры проектируют эти машины для использования на компьютере. И эти компьютеры фактически контролируют фактический процесс обработки детали и различных инструментов.

Следовательно, можно сказать, что быстрое прототипирование с ЧПУ - это фактически метод изготовления 3D-моделей. И инженеры производят и проектируют эти 3D-модели, пока не получат окончательный дизайн требуемого продукта.

Какие методы инженеры используют при создании прототипов с ЧПУ ?

Обычно есть два метода, которые производители используют при создании прототипов ЧПУ для создания .

Это:

- Обработка с ЧПУ

- Процесс 3D-печати.

Кроме того, в обоих вышеупомянутых производственных процессах инженеры используют два процесса для создания быстрых прототипов. Это:

- Резка

- Фрезерование

Инженеры называют эти методы «субтрактивным» производством. И инженеры называют эти методы «субтрактивным» производством.

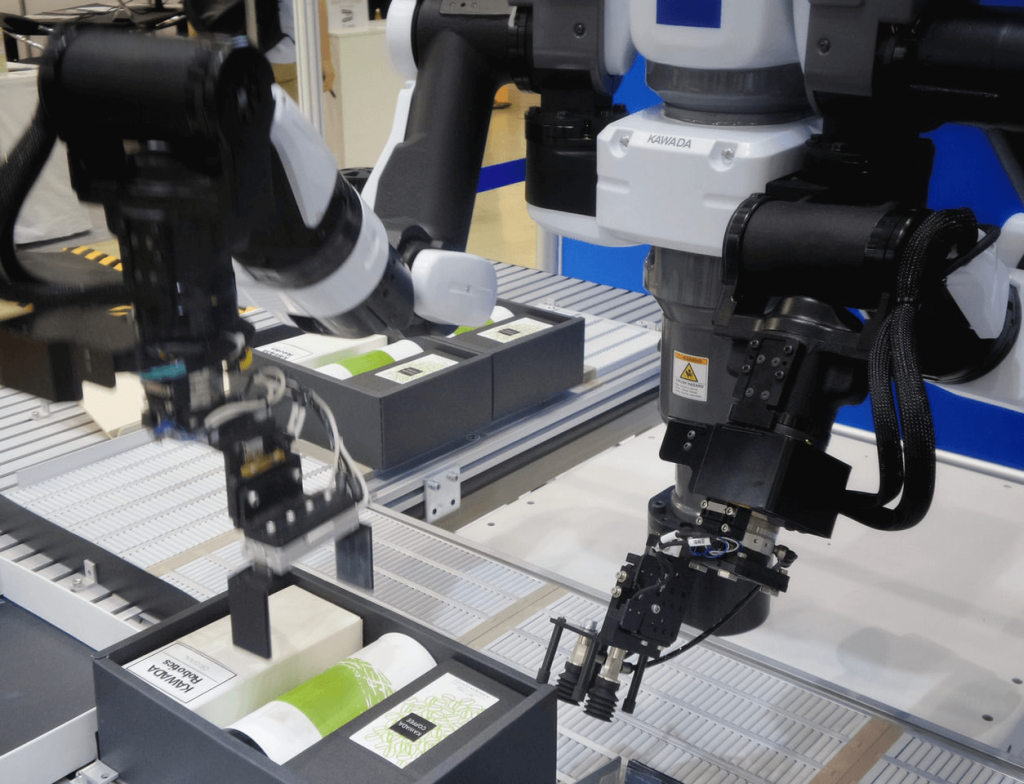

Nowadays great revolution has arrived in the industry of manufacturing of hardware. So, now anyone can invest and get benefit from this industry. But in earlier only big players had prevailed all over it.

All innovations become possible because of these modern methods of manufacturing. Hence, among all these processes CNC part rapid prototyping is best choice.

CNC rapid prototyping also has enabled Manufacturers to produce models of 3D prototype. So, that they can easily convert CNC part rapid prototype in final products. Manufacturers can fabricate several kinds of solid and concrete products with the help of this manufacturing process.

What are the advantages of CNC part rapid prototype by CNC machining?

Here we are providing you some benefits of CNC part rapid prototyping. And these prototypes are created with the help of CNC machining

Это:

- rapid response even on large scale

- trustworthy

- less costly

- safe and secure

Characteristic of CNC part rapid prototype

Rapid response even on large scale:

In order to provide the wanted results, prototype CNC machining need no extra time. Hence, manufacturers can easily create a product by saving time. It does not take much time in this procedure to create CNC prototypes.

If manufacturers want to make use of CNC machining in order to create large scale production, they can do. Furthermore, CNC part rapid prototype will occur in high precision as it can provide great rate even in high loads of work.

Moreover, these prototypes are relatively very close to the final design. But these results cannot occur by manual work. You can even set the size and shape of prototype according to your desires.

Trustworthy:

Rapid prototypes that engineers create via CNC machining have great level of accuracy. Hence, the resulting tools will obviously give high accurate results. Furthermore, they prevent to occur the error in tool even if it repeats the process by thousands of times.

Moreover, if human try to produce prototypes, they obviously need some rest. On the other hand, machines can work for more time without taking rest. So, to create CNC part rapid prototype with the help of machines is better than in comparison to human.

Low cost CNC part rapid prototype:

Создание прототипов с ЧПУ также обходится дешевле. Потому что в основном эти производственные машины автоматические и работают сами по себе. Таким образом, владельцам бизнеса не нужно тратиться на зарплату.

Более того, как мы знаем, эти методы производства позволяют создавать 100% точные прототипы. И они также с большой скоростью создают прототипы. Следовательно, все эти возможности делают прототипирование с ЧПУ более точным и экономичным.

Чтобы извлечь выгоду из этой процедуры, инженерам просто нужно наладить идеальный процесс с хорошим обслуживанием. Но чтобы все это настроить, не нужно больших сумм. Это очень простые процедуры.

Кроме того, вам понадобится сотрудник, который позаботится о ваших машинах. Более того, он лучше знает, как чистить и поддерживать в хорошем состоянии.

Надежно и надежно:

It is highly safe and secure method to create CNC part rapid prototype. So, there are no chances of danger for anybody. There is zero contact of human with machines in working hours. So, the chance of any kind of hazard in the workplace will be less.

Fewer workforce:

In this process of prototyping, you need at least two persons to keep maintenance. But in other machines you required a separate person for every separate operation. Working division among two people will be like this:

- first person will handle every part with the use of CNC software

- second person will just make the set up perfect for producing the essential designs

Why should manufacturers use CNC machining for CNC part rapid prototyping ?

There are many benefits of using CNC machines to create CNC part rapid prototype. And we have described all of them above. However, you have to keep in mind that you have managed all the possible threats related to your product.

There are very strict laws about the safety of human. And you have to obey all of them very strictly. If you will diverge from it, consequences can be dangerous.

But with the use of CNC machining you can avoid every possible risk of this type. And you can deal with every risk different from your product before it hits the market.

So, CNC machining is considered the best in every way. Hence, manufacturers use CNC machining, as it saves them from every kind of problem. And it’s a hazels free option for creating CNC part rapid prototype.

What are the applications of CNC part rapid prototype ?

The use of CNC part rapid prototyping has introduced the world of technology with a new and great innovation. Since,the use of computers has revolutionized the world of technology and CNC is at the forefront of this development.

CNC machining controls the following parts, like:

- grinders

- routers

They make use of computers in order to check the originality of the design. And also match the issues of potential with the final design. All this has performed to check and make sure if the final design does not possess any type of main problems.

Furthermore, all this helps in order to reduce the costs of manufacturing. Because the company may locate flaws and defaults before processing at the actual platform.

All the progress in the field of technology and science greatly rely on CNC part rapid prototype. And here are the other milling and cutting technologies:

- ultra-precision machining

- the application of ultra-high-speed cutting

- servo performance

- CNC system for CNC Rapid

- spindle drive

- Prototyping CNC Milling.

Hence, with the progress of computer technology and microelectronics, production of

Numerical control systems are improving with the passage of time. Furthermore, now the application of CNC prototyping has become essential in all the fields of numerical control technology. And it is also expanding day by day.

Hence, nowadays CNC part rapid prototype has become part and parcel in the progress of modern days technology and production of CNC rapid prototyping.