Кращі 5 стратегій швидкого прототипування деталей з ЧПУ для початківців

Що таке швидкий прототип з ЧПУ та з ЧПУ?

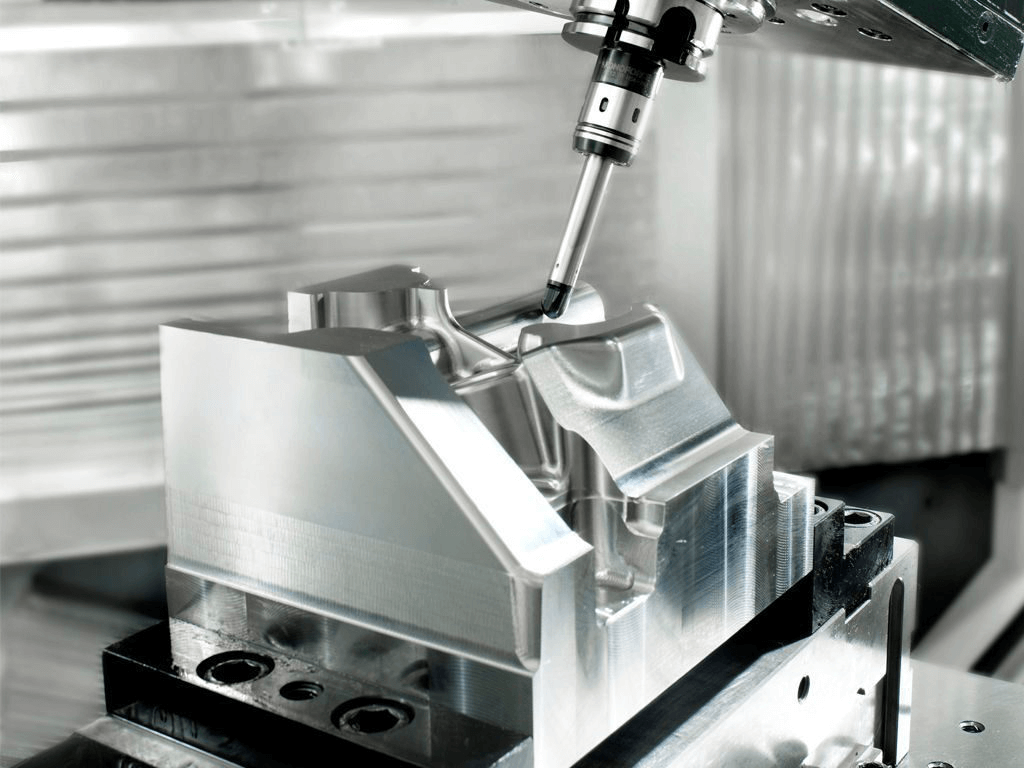

Швидкий прототип деталей з ЧПУ насправді створив за допомогою верстатів з ЧПУ. А інженери пояснюють, що CNC насправді є абревіатурою від Computer Numeric Control. В основному це набір машин. Він швидко створює прототипи.

Крім того, інженери проектують ці машини для використання на комп'ютері. І ці комп’ютери фактично керують реальним процесом заготовки та різними інструментами.

Hence, we can say that CNC rapid prototyping is in fact a method of manufacturing 3D models. And engineers fabricate and design these 3D models until they get the final design of required product.

Which methods engineers use in CNC prototyping to create CNC parts and rapid prototype ?

There are generally two methods which manufacturers use in CNC prototyping to create CNC part rapid prototype.

Це:

- Обробка з ЧПУ

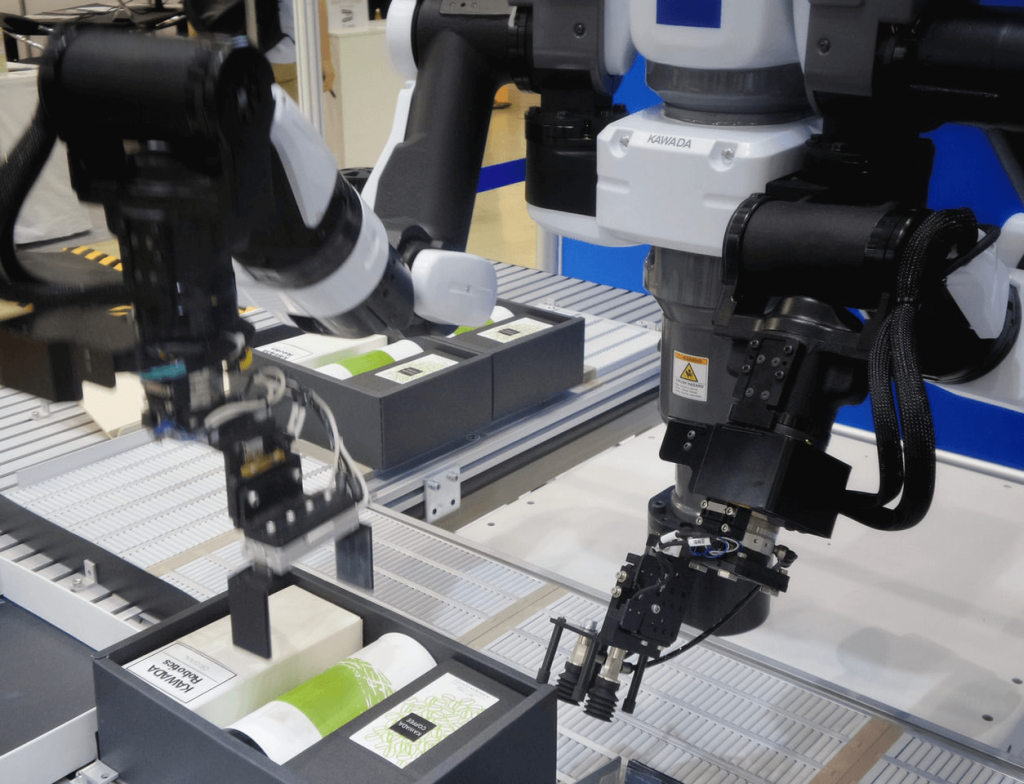

- 3D printing process.

Furthermore, in both of above manufacturing processes, engineers use two processes to create rapid prototypes. These are:

- Cutting

- Milling

Engineers refer these methods as “subtractive “manufacturing. And engineers refer these methods as “subtractive” manufacturing.

Nowadays great revolution has arrived in the industry of manufacturing of hardware. So, now anyone can invest and get benefit from this industry. But in earlier only big players had prevailed all over it.

All innovations become possible because of these modern methods of manufacturing. Hence, among all these processes CNC part rapid prototyping is best choice.

CNC rapid prototyping also has enabled Manufacturers to produce models of 3D prototype. So, that they can easily convert CNC part rapid prototype in final products. Manufacturers can fabricate several kinds of solid and concrete products with the help of this manufacturing process.

What are the advantages of ЧПУ by CNC machining?

Тут ми надаємо вам деякі переваги швидкого прототипування деталей з ЧПУ. І ці прототипи створюються за допомогою обробки з ЧПУ

Це:

- швидке реагування навіть у великих масштабах

- надійний

- дешевше

- безпечний і надійний

Характеристика ЧПУ

Швидка реакція навіть у великих масштабах:

Для того, щоб отримати бажані результати, прототипу з ЧПУ не потрібно зайвий час. Отже, виробники можуть легко створити продукт, заощаджуючи час. У цій процедурі не потрібно багато часу для створення прототипів з ЧПУ.

Якщо виробники хочуть використовувати обробку з ЧПУ, щоб створити масштабне виробництво, вони можуть це зробити. Крім того, ЧПУ буде виконуватися з високою точністю, оскільки він може забезпечити велику швидкість навіть при великих навантаженнях.

Moreover, these prototypes are relatively very close to the final design. But these results cannot occur by manual work. You can even set the size and shape of prototype according to your desires.

Trustworthy:

Rapid prototypes that engineers create via CNC machining have great level of accuracy. Hence, the resulting tools will obviously give high accurate results. Furthermore, they prevent to occur the error in tool even if it repeats the process by thousands of times.

Moreover, if human try to produce prototypes, they obviously need some rest. On the other hand, machines can work for more time without taking rest. So, to create ЧПУ with the help of machines is better than in comparison to human.

Low cost CNC part rapid prototype:

CNC prototyping is also less costly. Because basically these manufacturing machines are automatic and they work on their own. So, the owners of business do not need to spend money on salaries.

Moreover, as we know that these manufacturing methods create 100 % accurate prototypes. And they also create prototypes with great speed. Hence, all these abilities make CNC prototyping more accurate and money saving.

To get benefits from this procedure, engineers just need to set a perfect process with good maintenance. But to make all this set up, there is no need of large amounts. They are highly low-cast procedures.

Furthermore, you will need an employee who can take good care of your machines. What’s more, he has a better knowledge to clean and keep good maintenance.

Safe and secure:

It is highly safe and secure method to create ЧПУ. So, there are no chances of danger for anybody. There is zero contact of human with machines in working hours. So, the chance of any kind of hazard in the workplace will be less.

Fewer workforce:

In this process of prototyping, you need at least two persons to keep maintenance. But in other machines you required a separate person for every separate operation. Working division among two people will be like this:

- first person will handle every part with the use of CNC software

- second person will just make the set up perfect for producing the essential designs

Why should manufacturers use CNC machining for CNC part rapid prototyping ?

There are many benefits of using CNC machines to create ЧПУ. And we have described all of them above. However, you have to keep in mind that you have managed all the possible threats related to your product.

There are very strict laws about the safety of human. And you have to obey all of them very strictly. If you will diverge from it, consequences can be dangerous.

But with the use of CNC machining you can avoid every possible risk of this type. And you can deal with every risk different from your product before it hits the market.

So, CNC machining is considered the best in every way. Hence, manufacturers use CNC machining, as it saves them from every kind of problem. And it’s a hazels free option for creating ЧПУ.

What are the applications of ЧПУ ?

The use of CNC part rapid prototyping has introduced the world of technology with a new and great innovation. Since,the use of computers has revolutionized the world of technology and CNC is at the forefront of this development.

CNC machining controls the following parts, like:

- grinders

- routers

They make use of computers in order to check the originality of the design. And also match the issues of potential with the final design. All this has performed to check and make sure if the final design does not possess any type of main problems.

Furthermore, all this helps in order to reduce the costs of manufacturing. Because the company may locate flaws and defaults before processing at the actual platform.

Весь прогрес у галузі техніки та науки значною мірою залежить від ЧПУ . А ось інші технології фрезерування та різання:

- надточна обробка

- застосування надшвидкісного різання

- продуктивність сервоприводу

- Система ЧПУ для ЧПУ Rapid

- привід шпинделя

- Прототипування фрезерування з ЧПУ.

Отже, з розвитком комп'ютерних технологій та мікроелектроніки, виробництво

Числові системи управління вдосконалюються з плином часу. Крім того, зараз застосування прототипування з ЧПУ стало важливим у всіх областях технології числового управління. І він також розростається з кожним днем.

Отже, на сьогоднішній день ЧПУ став невід'ємною частиною прогресу сучасних технологій та виробництва швидких прототипів з ЧПУ.